Reactors and Pressure Vessels

IRIAN MECATRONICS develops custom reaction systems for scientific research and pilot testing. Our engineering department supports you in defining equipment adapted to specific operating conditions, ensuring the safety, repeatability, and precision of your measurements.

Engineering for Experimental Research

The implementation of high-pressure, high-temperature (HPHT) experiments requires equipment specifically designed to meet the constraints of the process. Whether dealing with multiphase systems (gas-liquid-solid) or chemically corrosive environments, we design each reactor as a scientific instrument, where every component is selected for its performance and reliability.

Our approach is based on a detailed analysis of your specifications to deliver a robust, fully validated, and “plug and play” technical solution.

Custom Performance. Standard Cost.

Custom equipment doesn’t mean starting from a blank slate for every project. Our design approach is based on integrating proven “design blocks” for essential functions (e.g., agitation systems, sealing, and regulation).

Our engineers combine these reliable, standardized modules with elements designed specifically for your needs to create high-performance equipment that is optimized in terms of cost and lead time. This gives you a solution perfectly adapted to your process, with the robustness of field-tested components and a controlled budget comparable to a standard solution.

Operating Parameters and Vessel Design

Operating Range: The volume, working pressure, and temperature are defined to match your specific testing conditions.

Wetted Materials: We select materials (316 Stainless Steel, Nickel alloys, Titanium, etc.) and seal elastomers (FFKM, etc.) based on chemical compatibility with your reactants and the thermal conditions.

Ports and Connections: The reactor head is configured with the necessary number of ports for instrumentation, fluid injection, sampling, and safety devices.

Magnetically Driven Stirring System

Reaction Environment Integrity: The use of a magnetic drive ensures a hermetic seal by separating the motor assembly from the pressurized zone. This dynamic seal-free design prevents any risk of leakage and contamination.

Controlled Hydrodynamics: Various impellers (e.g., gas-inducing turbines for gas entrainment, anchor stirrers) can be fitted to generate the mixing profile required by your process.

Optimized Thermal Design: The architecture (offset motor, ceramic bearings, high-temperature magnets) is engineered for stable operation even at high tempera

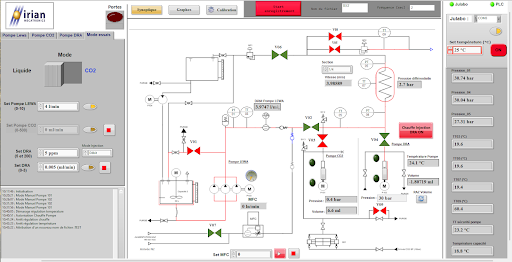

Control and Data Acquisition

Full System Control: Our control system, built around a Programmable Logic Controller (PLC) and a Human-Machine Interface (HMI) on a PC, is developed entirely by our own control systems engineers. This guarantees deep customization and direct, expert support.

Fine-Tuned Process Management: The user interface enables the configuration of precise setpoints and programmed ramps for parameters like agitation speed, temperature, and pressure.

Comprehensive Data Logging: All sensor readings, including pressure, temperature, and torque, are recorded, displayed live on-screen, and can be easily exported for detailed analysis.

Aras of Application

Our equipment is used in fundamental and applied research laboratories for studies in:

-

Heterogeneous and Homogeneous Catalysis

-

Organic and Inorganic Synthesis

-

Process Engineering

-

Polymer Chemistry

-

Materials Science and Corrosion

-

Biomass Valorization