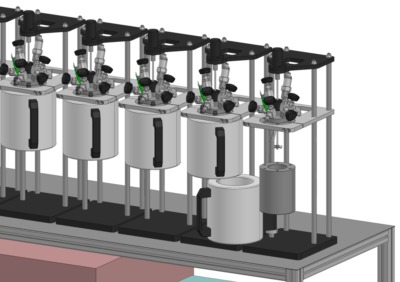

High pressure and high temperature reactors

The high-pressure, high-temperature (HP-HT) bench comprises six reactors designed to investigate biogeochemical processes in gas storage aquifers after the injection of oxygen-enriched or hydrogen-enriched biogas. The primary objective of this bench is to study the influence of various operating parameters on these processes and assess the reproducibility of the experiments. Of particular interest is the impact of biogeochemical processes on the sulfur cycle, including the production of hydrogen sulfide (H2S).

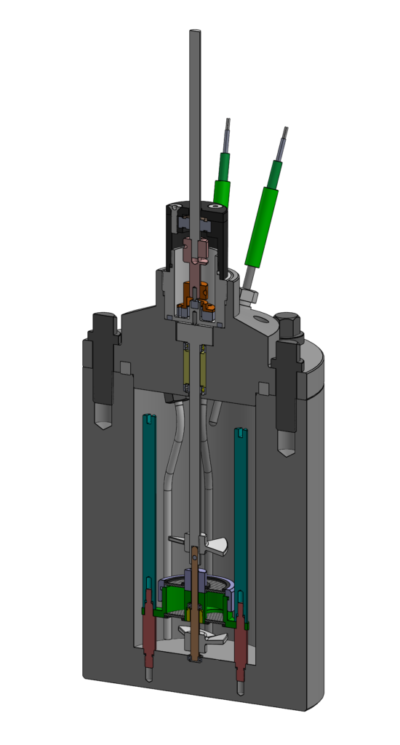

Each reactor within the bench is capable of operating at high pressures and temperatures, simulating conditions encountered in gas storage aquifers. The reactors are equipped with precise pressure control systems to maintain the desired operating pressures, while temperature control mechanisms ensure accurate regulation of the experimental conditions. These capabilities enable researchers to replicate and study the biogeochemical processes occurring within gas storage aquifers with high fidelity.

The bench facilitates the injection of biogas enriched with either oxygen or hydrogen into the reactors, simulating realistic gas storage scenarios. The injection system ensures controlled and consistent delivery of the enriched biogas into the reactors, allowing researchers to investigate the effects of these gases on the biogeochemical processes.

The experiments conducted on the bench aim to explore the influence of different operating parameters on the biogeochemical processes. These parameters may include injection pressure, gas composition, residence time, and others. By systematically varying these parameters, researchers can assess their impact on the processes under investigation, gaining insights into the factors that drive or inhibit the desired biogeochemical reactions.

A key focus of the bench’s studies is the production of hydrogen sulfide (H2S) and its role in the sulfur cycle. Researchers closely monitor the formation and behavior of H2S, as it represents a significant challenge and concern in gas storage environments. Understanding the factors that influence H2S production and its potential mitigation strategies is crucial for ensuring safe and sustainable gas storage operations.

The HP-HT bench provides a controlled and reproducible platform for studying biogeochemical processes in gas storage aquifers. Its multi-reactor configuration allows for simultaneous testing of different parameters, enhancing the efficiency and productivity of the experimental studies. The insights gained from these studies contribute to the understanding of biogeochemical reactions, their impact on the sulfur cycle, and the development of strategies to optimize gas storage operations.

TECHNICAL SPECIFICATIONS

> Maximum operating pressure : 150 bar absolute

> Vacuum pressure : 0,1 bar absolute

> Maximum operating temperature: 150°C

> Maximum temperature of the heating system : 200°C

> Useful volume of the reactor: 440 cm3

> Reactor material: Hastelloy C276

> Basket material : Stainless steel 316L

> Motorized stirring: magnetic drive – double helix – speed up to 200 rpm

> Measurements per reactor: 1 liquid temperature, 1 gas temperature, 1 internal pressure

> Safety devices per reactor: 1 independent overpressure safety device, 1 rupture disk, 1 independent overheating safety device

> Certification : Reactors built according to PED methodology (Pressure Equipment Directive)