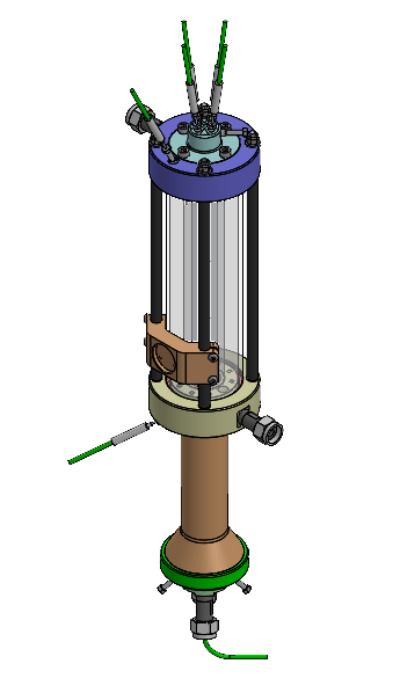

CO2 Hydrate Formation Testing Rig

This specialized CO2 testing rig has been designed at the request of the PERL. It is equipped with a sapphire tube to measure hydrate formation through two configurations: one with a sand pack and the other utilizing torque measurement via magnetic stirring.

Structure and Components: The testing rig consists of a robust frame made of profiles, accommodating three main components:

- CO2 Column with Sapphire Tube: This column is integral for the measurement of hydrate formation under controlled conditions.

- Separation Column: This component facilitates the separation of fluids post-experimentation, ensuring accurate data collection.

- Discharger: Positioned downstream to maintain pressure within the system, enhancing the overall reliability of the setup.

Installation and Setup: The entire assembly is designed to be installed on a workbench or any support structure with a height of approximately 90 cm. This ergonomic design ensures ease of access and operation for users.

Instrumentation and Controls: The equipment is outfitted with multiple sensors for pressure and temperature measurements, along with two flowmeters:

- The first flowmeter is installed on the CO2 injection line.

- The second flowmeter is positioned after the separation column to monitor fluid flow accurately.

Manual valves and check valves are strategically placed throughout the rig to ensure proper fluid management. The arrangement of components is meticulously designed to minimize dead volumes, thereby optimizing the efficiency of the testing process.

Data Acquisition System: An integrated computer system enables the acquisition and monitoring of various pressure, temperature, and flow rate values, facilitating real-time data analysis.

Fluid Injection System: Fluid injection is carried out by two high pressure syringe pumps, which are connected to the rig’s input ports, allowing for precise control over the experimental conditions.

Safety Features: For user safety, all components are housed within a protective frame equipped with doors and plexiglass panels, providing complete visibility of the testing process while ensuring protection from potential hazards.