Extreme Environment Simulation Systems / Geoscience & Subsurface Studies / Test Benches & Experimental Pilot Units

Custom HPHT Triaxial Testing Press for Geomechanics Research

A major university research center in geosciences, specializing in studying rock behavior under extreme conditions, sought to accurately replicate deep geological environments in the laboratory. IRIAN MECATRONICS met the challenge by designing and manufacturing a custom High Pressure High Temperature (HPHT) triaxial testing press, capable of applying complex stresses while offering high measurement accuracy and resistance to aggressive fluids.

The Challenge: Simulating Extreme Geomechanical Conditions with Unparalleled Precision

The laboratory required versatile equipment to finely characterize the mechanical and hydraulic properties of rocks. The specifications demanded cutting-edge performance and high reliability for potentially long-duration tests:

Apply and regulate isostatic confining pressure up to 150 MPa with ±0.2 MPa accuracy.

Control pore fluid pressure up to 100 MPa with ±0.2 MPa accuracy.

Generate axial stress on the sample (Ø 20 mm x 40 mm ) up to 500 MPa, measured with ±0.2 MPa accuracy.

Maintain the sample at a homogeneous temperature up to 150°C, controlled within ±5°C.

Measure axial strain (±1 µm ) and pore volume (±0.001 cm³ ) with very high resolution.

Enable permeability measurements covering a wide range, from 10⁻¹³ m² down to 10⁻¹⁷ m².

Guarantee chemical compatibility of the pore pressure circuit with potentially corrosive fluids (strong acids/bases).

Offer flexible control modes (constant displacement or constant pressure ) with guaranteed long-term stability.

Our Solution: A Robust, Precise, and Modular Triaxial Press

Leveraging its experience in designing HPHT geomechanical equipment, IRIAN MECATRONICS developed a comprehensive system incorporating targeted technical choices to meet every requirement:

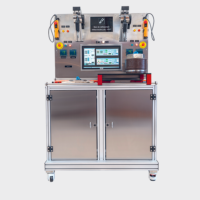

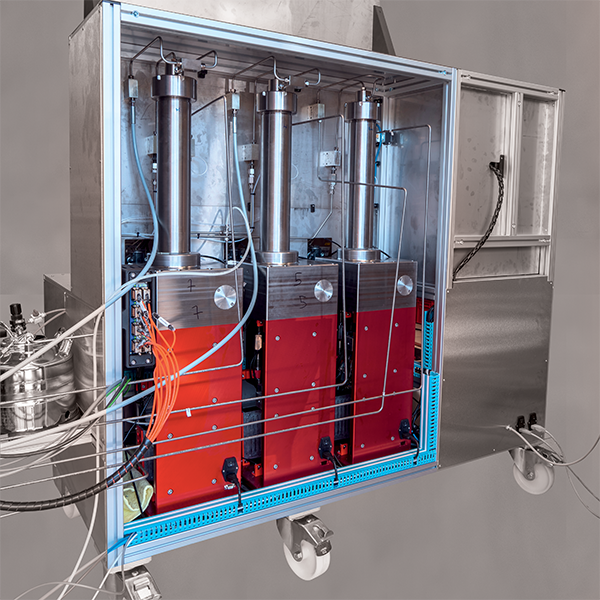

Reliable Architecture: The design builds upon a proven configuration, similar to systems previously delivered to international research centers , featuring a separate test cell and control bench for enhanced flexibility and safety.

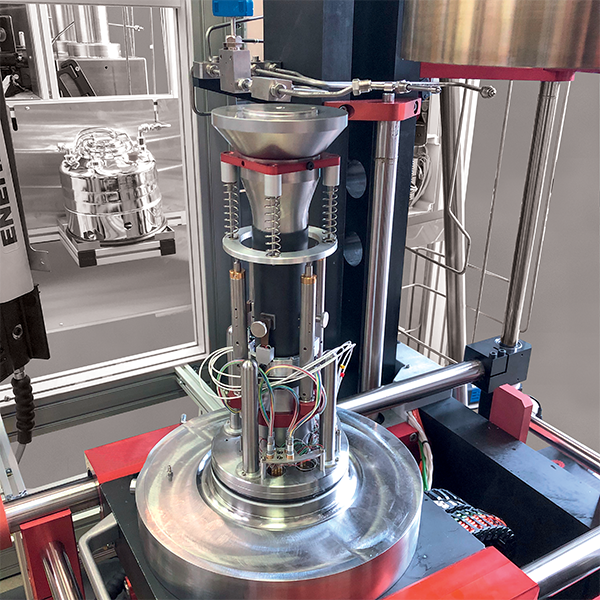

Optimized HPHT Cell: The core of the press uses a high-strength stainless steel body for the confining pressure. For the pore pressure circuit, exposed to aggressive fluids, Inconel 625 was selected for its outstanding chemical resistance , complemented by FFKM seals.

Stable Pressure Generation: Confining and pore pressures are generated by high-pressure dual-piston dosing pumps. This key technology ensures perfectly continuous and pulse-free flow, essential for long-term stability and accurate ultra-low permeability measurements. Axial pressure is managed by a similar pump.

High-Resolution Instrumentation: The system integrates leading-edge sensors: a high-capacity axial load cell , LVDT for piston displacement measurement (with an advanced option for LVDTs directly on the sample for ultra-precise strain measurement ), Type T thermocouples , and high-accuracy pressure transducers positioned as close as possible to the cell .

Precise Thermal Control: A thermally insulated mica band heater provides rapid heating and precise temperature regulation (±1°C ) up to 150°C (extendable to 200°C ).

Comprehensive and Safe Control: A Programmable Logic Controller (PLC) manages all functions via a PC-based Human-Machine Interface (HMI) (LabVIEW integration possible ). It allows for programming complex test cycles (ramps, steps), real-time visualization, and full data logging . Multiple hardware and software safety interlocks ensure safe operation under all conditions .

Scalability: The design allows for future integration of options such as ultrasonic transducers for P & S wave measurements .

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.