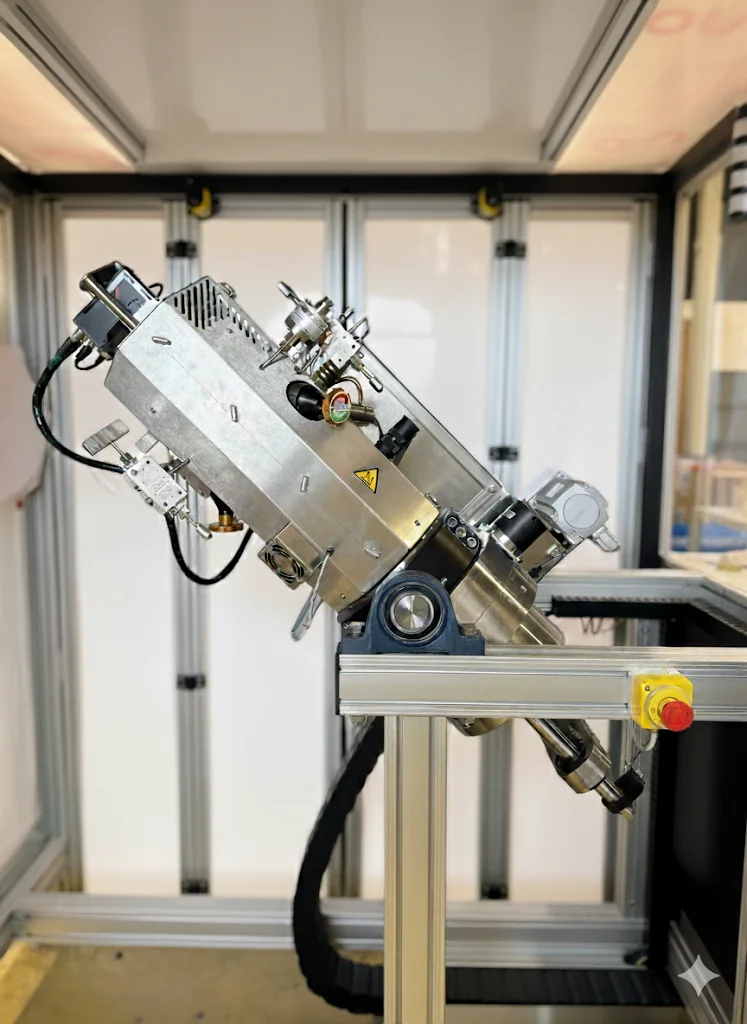

Full visibility PVT cell

Our PVT cell is an advanced instrument for oil and gas analysis of downhole samples. It can function as a standalone unit or be combined with auxiliary equipment to perform complex tasks and deliver reliable results. Its adaptability allows it to handle both gas and fluid analysis without modifications. The design phase emphasized maximizing measurement quality and improving repeatability through automation, which helps reduce uncertainty and enhance the accuracy of reservoir measurements.

Measurements

Our PVT cell with accessories is designed to perform:

- A comprehensive PVT study on oil and volatile oil encompassing the following components:

- Determination of bubble point

- Composition Flash analysis

- Constant Composition Expansion at constant temperature

- Differential vaporization at constant temperature

- Separation tests conducted over multiple stages at varying temperatures

- Measurement of viscosity

- A complete PVT study on gas condensate:

- Determination of dew point

- Constant mass depletion analysis

- Constant volume depletion analysis

- A recombination of separator oil or condensate and separator gas under reservoir conditions

- Liquid / solid equilibrium (for wax, asphalts, hydrates)

- An analysis of viscosity, density, composition (accessories available as an option)

- Compressibility factor determination (Z factor)

- Dew point and bubble point determination

- Gas in Oil Ratio (requires GOR apparatus)

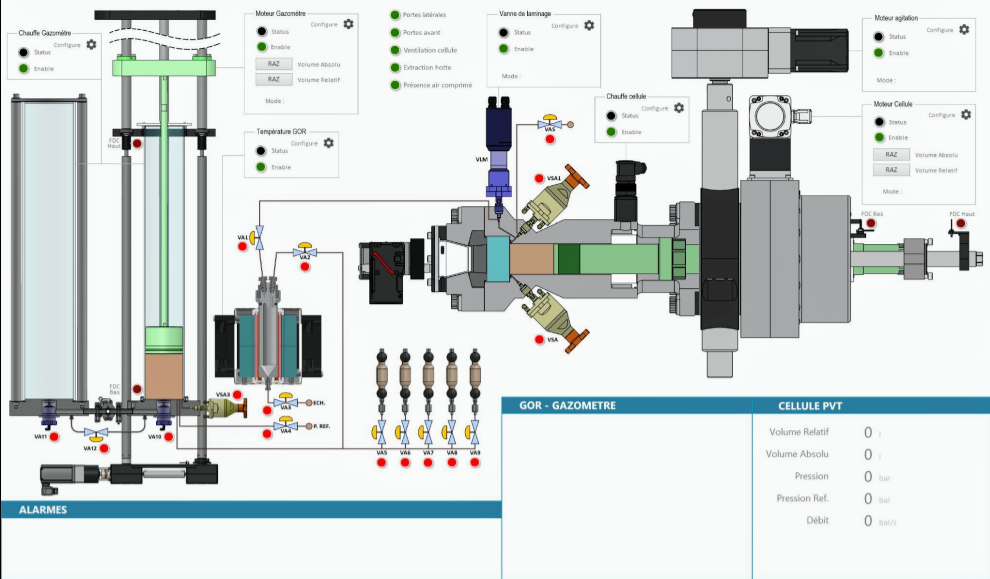

Control

The PVT cell is controlled via a human/machine interface developed on Labview. It provides control over the PVT cell and gas meter on a single screen.

The interface displays valve and sensor statuses, transducers measurement and provide a graphical display of the cell and gasmeter.

The interface has automated sequence for the following tests:

- Recombination of separator oil or condensate and separator gas under reservoir conditions

- Compressibility factor determination (Z factor)

- Dew point and bubble point determination

Further test sequence could be added, depending on the customer available equipment. Pressure sensor calibration will be done automatically thanks to the reference pressure sensor integrated in both instruments.

The interface also provides manual control·over the following components:

- Shear valve (open /close / position)

- Semi-automated valves (open / close)

- Motor, controlled by flow setpoint, pressure setpoint (with or without ramp), or pressure regulation

- Tilting motor (position / cycle)

Full laboratory automation and custom equipment integration is also possible provided that communication protocols of third party equipment are compatible with our equipment.

Cell

The cell is equipped with a high pressure, high transparency, sapphire window. The full visibility feature, enhanced by an integrated high-resolution camera, significantly improves the repeatability and accuracy of experimental processes by providing real-time visual monitoring of fluid behavior.

By automating the data acquisition process, this system reduces human intervention, ensuring consistent experimental conditions across multiple tests.

Moreover, the camera’s continuous observation allows for immediate detection of anomalies or phase transitions, which can be critical for maintaining sample integrity and process reliability.

Additionally, this automation minimizes the need for direct human involvement in high-pressure environments, thereby increasing operator safety and reducing the risk of exposure to hazardous conditions.

We have minimized dead volumes to the greatest extent possible in order to significantly enhance the precision of results and reduce measurement uncertainty.

By eliminating areas where fluids can stagnate or become trapped, we ensure that the system operates with maximum accuracy, delivering cleaner, more consistent data. This reduction in dead volume also prevents cross-contamination between experiments, which is crucial for maintaining the integrity of each sample.

As a result, the measurements are not only more reliable but also more repeatable, providing a higher degree of confidence in the experimental outcomes.

Total dead volume: < 0.5% of cell volume