High-flow - Large volume pump

Double pump system with a wide flow range and high volume, used as a standard for water meters.

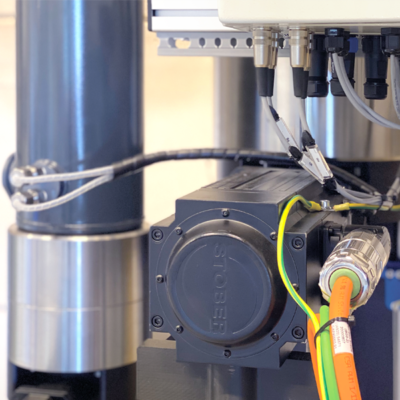

The double pump system consists of two parallel pumps connected in tandem. Each pump is capable of operating independently, but they are synchronized to work together for enhanced performance.

The first pump, referred to as the low-flow pump, is designed to handle lower flow rates within the meter’s measurement range. It is highly precise and offers exceptional accuracy for low-flow applications. The low-flow pump ensures accurate measurement even at the minimum flow rate.

The second pump, known as the high-flow pump, is responsible for handling higher flow rates. It is designed to provide a broader flow range and accommodate larger volumes of water. The high-flow pump maintains accuracy and reliability even at the upper end of the meter’s measurement range.

The two pumps work in synchronization to cover the entire flow range of the water meter. When the flow rate is low, the low-flow pump operates, accurately measuring the water passing through the meter. As the flow rate increases beyond the capacity of the low-flow pump, the high-flow pump kicks in, seamlessly taking over to maintain accurate measurements.

This double pump system serves as a calibration standard for water meters, ensuring their accuracy and reliability across a wide range of flow rates and volumes. It provides a reference point against which other water meters can be calibrated and verified, ensuring consistent and precise measurements for various water consumption applications.

TECHNICAL SPECIFICATIONS

CYLINDER PRESSURE CAPACITY: 25bar (360psi)

FLOW RATE (LITER/HOUR):

> Pump P1: de 0.013 à 100

> Pump P2: de 100 à 6,000

VOLUME:

> Pump P1: 3 Liters

> Pump P2: 30 Liters

WORKING TEMPERATURE: +20°C up to +50°C

MATERIAL: Stainless steel 316L