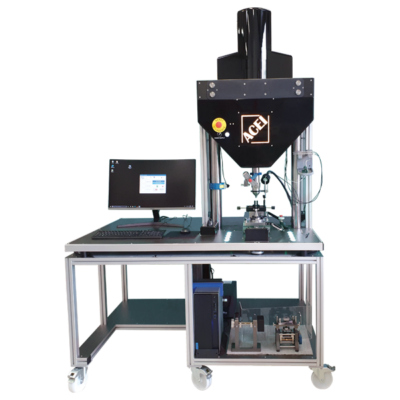

Combine uniaxial tester

The Combined UniAxial Tester is a servo-electric loading press machine specifically designed to perform two types of tests for the mechanical characterization of petroleum rock samples.

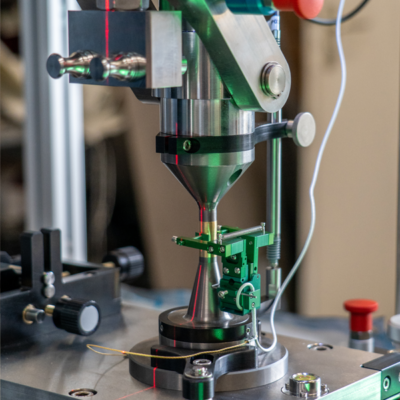

The first type of test conducted is uniaxial compression (UCS) on cylindrical samples with a diameter of 10 mm. This test allows for the determination of important parameters such as the modulus of elasticity and the Poisson’s ratio, which are essential for assessing the mechanical response of rock samples under compression loads.

The second type of test performed is the tensile test on pre-cracked cylindrical samples. This test aims to determine the fracture toughness K1c, which measures the resistance of a material to crack propagation. It enables the evaluation of the ability of rock samples to withstand fracture and absorb energy during the fracture process.

The Combined UniAxial Tester machine is equipped with a servo-electric loading system, which allows for controlled and precise application of forces to the rock samples. This system offers high reliability and accuracy in applying loads, ensuring reliable and reproducible test results.

Through these two types of tests, the Combined UniAxial Tester enables a comprehensive characterization of the mechanical properties of petroleum rock samples. The information obtained from these tests is crucial for understanding the behavior of rocks under drilling and petroleum production conditions, and for guiding the design and optimization of petroleum operations.