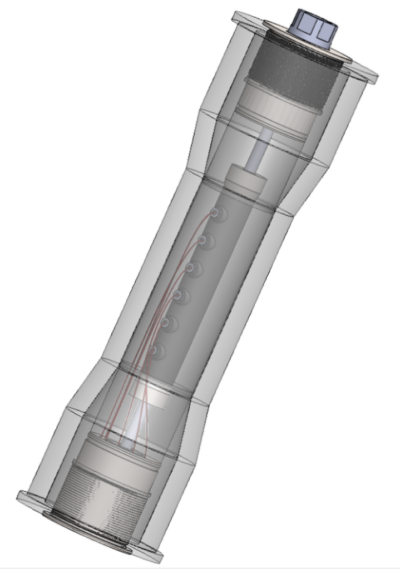

High-Pressure X-Ray Testing Cell

Developed in response to a request from BRGM, this X-ray transparent triaxial reactive cell is expertly engineered for in-situ testing coupled with X-ray radiation. All materials surrounding the sample have been meticulously selected to ensure minimal X-ray attenuation, meeting the rigorous specifications set forth.

The equipment comprises the triaxial cell, loading devices, and pressure-volume controllers (PVCs) for permeability testing. It is fully operational, ensuring seamless execution and management of experiments in accordance with the defined criteria.

Material Selection

The materials utilized in the construction of the cell are transparent to X-rays and possess the necessary mechanical properties to withstand compressive pressures exceeding several tens of megapascals (MPa). The design has been carefully executed to minimize wall thickness around the sample, adhering to the required specifications for mechanical strength and stress levels.

Sample Dimensions

This cell accommodates cylindrical samples with a targeted diameter of 10 mm and an aspect ratio of 2. It also allows for variable diameters ranging from 5 mm to 20 mm, providing flexibility for various experimental needs.

Loading Pressure

The design allows for the application of variable axial loads, achieving a maximum loading pressure of several tens of MPa (≥ 25 MPa). This capability has been integrated to support a wide range of experimental requirements.

Confinement Pressure

The cell is designed to generate confinement pressure around the sample, effectively preventing deformation under loading conditions. This aspect has been thoroughly incorporated into the overall design to ensure reliable test results.

Temperature Range

The cell is capable of heating samples to temperatures of ≤ 200 °C, with additional provisions for cooling to ≤ -20 °C. This functionality meets the critical temperature range specified for testing.

Fluid Circulation

Engineered for the injection and circulation of fluids (water, oil, gas) through the sample, the cell is equipped to measure permeability accurately. The system allows for precise control over fluid flow, conforming to the specified range of permeability parameters from 10⁻¹² to 10⁻²¹ m²/s.

Pore Pressure Measurement

The design includes the capability to measure pore pressure, ensuring comprehensive data collection during testing.

Cell Design Considerations

The dimensions of the triaxial cell have been optimized for proximity to the X-ray tube, fully complying with the technical specifications provided upon request. The overall size and aspect ratio of the cell are aligned with the requirements outlined, specifically achieving a minimum aspect ratio of 212 mm based on the dimensions of the X-ray tube.