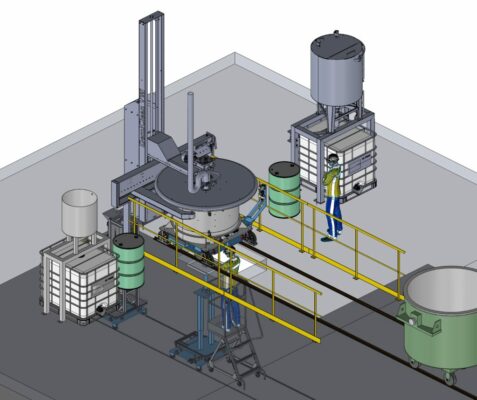

Automated tank cleaning system

As part of a collaboration with an important French defense company, Irian Mecatronics designed and manufactured a complete set of custom cleaning and maintenance systems for tanks used in sensitive production processes.

The project includes:

Automated cleaning machines for tank shells, bottoms, and swan necks,

Special tools for disassembly and reassembly of bottom valves,

Secure workstations dedicated to manual cleaning,

Leak testing equipment,

Air extraction systems to reduce operator exposure.

These solutions were developed to meet demanding requirements in terms of safety, ergonomics, and operational efficiency.

From design to on-site installation, our team managed the entire project: engineering, manufacturing, commissioning, and operator training.

This achievement illustrates our ability to support strategic actors in complex environments by delivering tailor-made equipment that combines performance and reliability.