High-Pressure Reactor 550 bar in Alloy 625 for Geoscience Research

For its geoscience research programs, BRGM entrusted IRIAN MECATRONICS with the design and manufacturing of a custom high-pressure (550 bar) and high-temperature (250°C) reactor. The project involved developing a versatile, tailor-made piece of equipment capable of withstanding highly corrosive fluids, including gas mixtures containing H2S.

Combining Versatility and Resistance

BRGM defined a precise set of specifications for a laboratory tool intended for studying rock samples under severe conditions. The main requirements were as follows:

Chemical Resistance: Full compatibility with various fluids, including water, brine, N2, H2, CO2, and CH4+H2S mixtures.

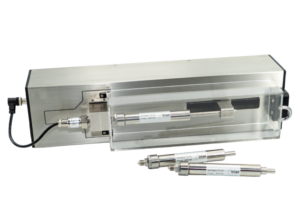

Operational Flexibility: The reactor needed to support three operating modes: standard Batch (with or without a PTFE liner), Batch with a gas head (via a floating piston), and Percolation through rock cores.

Instrumentation Integration: The design had to include specific ports for measurement probes (pH, ORP) to monitor reactions in real-time.

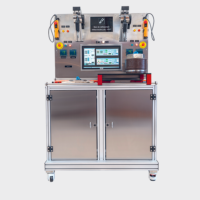

Control and Data Acquisition: The system was required to centralize thermal regulation and signal acquisition (pressure, piston position) through an external control unit with Ethernet/IP connectivity.

Compliance and Safety: The equipment had to be certified according to the Pressure Equipment Directive (PED 2014/68/EU) and include a dual safety system against overpressure.

To meet these requirements, our engineering department developed a pragmatic and robust technical solution.

The choice of materials was decisive: Alloy 625 was selected for all wetted parts due to its proven high resistance to corrosion, especially in the presence of H2S. To ensure reliable, long-term sealing, a combination of high-performance seals (FFKM, PEEK, PTFE) was used, supplemented by a PTFE surface treatment on the internal walls.

The modular design of the reactor’s lid and body allows the user to easily switch between configurations. The floating piston is equipped with an LVDT displacement sensor, ensuring precise measurement of volume variations.

Experimental performance is ensured by a remote control unit that manages temperature regulation and centralizes signal acquisition. Safety is guaranteed by two independent devices: a mechanical safety valve set at 550 bar and an electronic heating cut-off in case of overpressure.