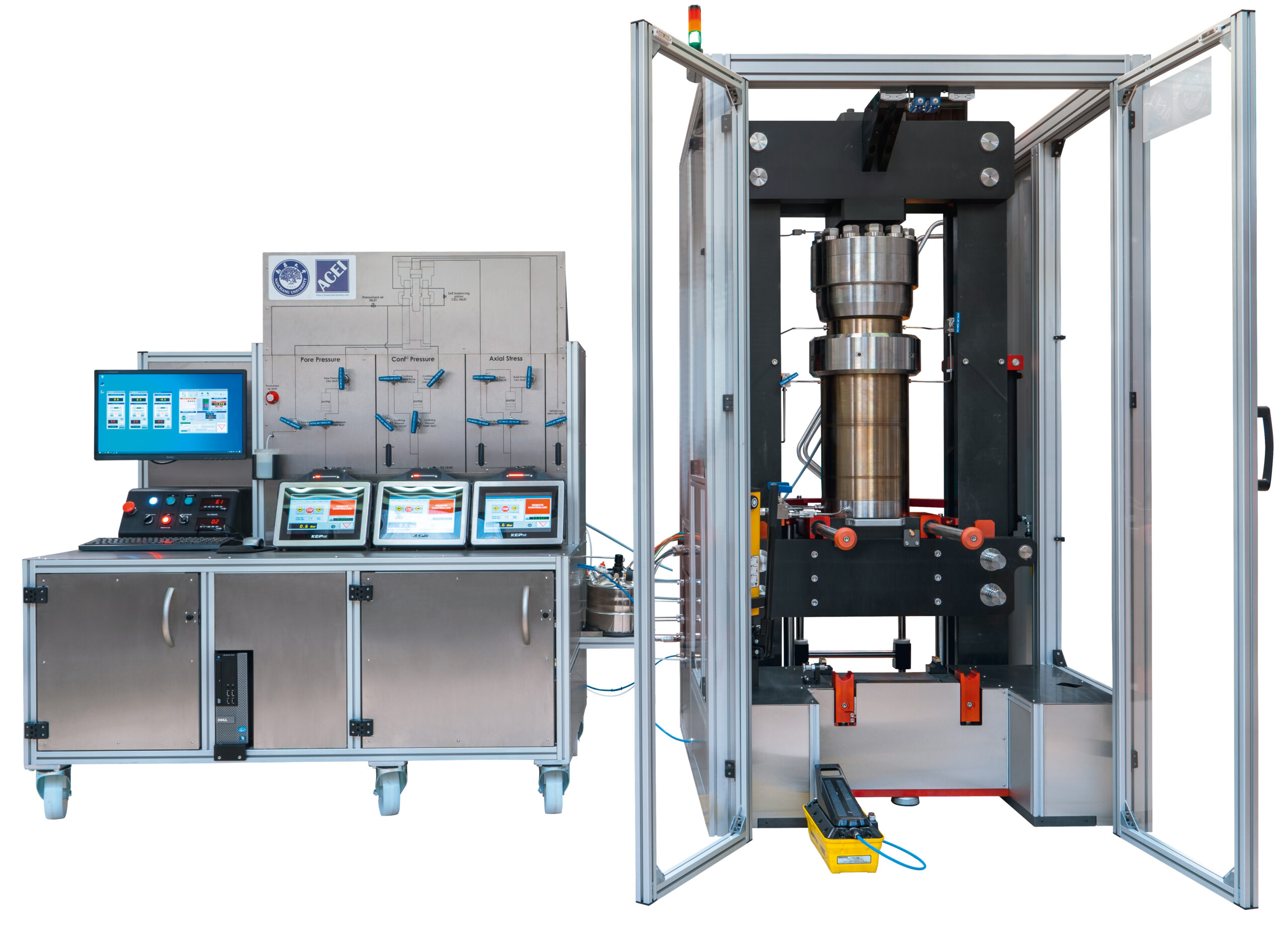

High Pressure High Temperature (HPHT) Triaxial Testing Systems

Replicating Deep Geological Conditions in the Laboratory

Triaxial testing systems are essential tools for research in geomechanics, petroleum engineering, civil engineering, and material science. They allow rock, soil, or other material samples to be subjected to controlled pressure (confining, pore pressure) and temperature stresses, thus simulating conditions encountered at depth.

At IRIAN MECATRONICS, we leverage our expertise in HPHT design to develop fully customized, robust, and precise triaxial presses. We tailor each system to meet the most demanding specifications of research laboratories and industrial R&D centers.

Multi-Stress Simulation and Advanced Characterization Tailored to Your Project

Our triaxial systems are designed to independently apply and control several key parameters, enabling fine characterization of material behavior according to your specific needs:

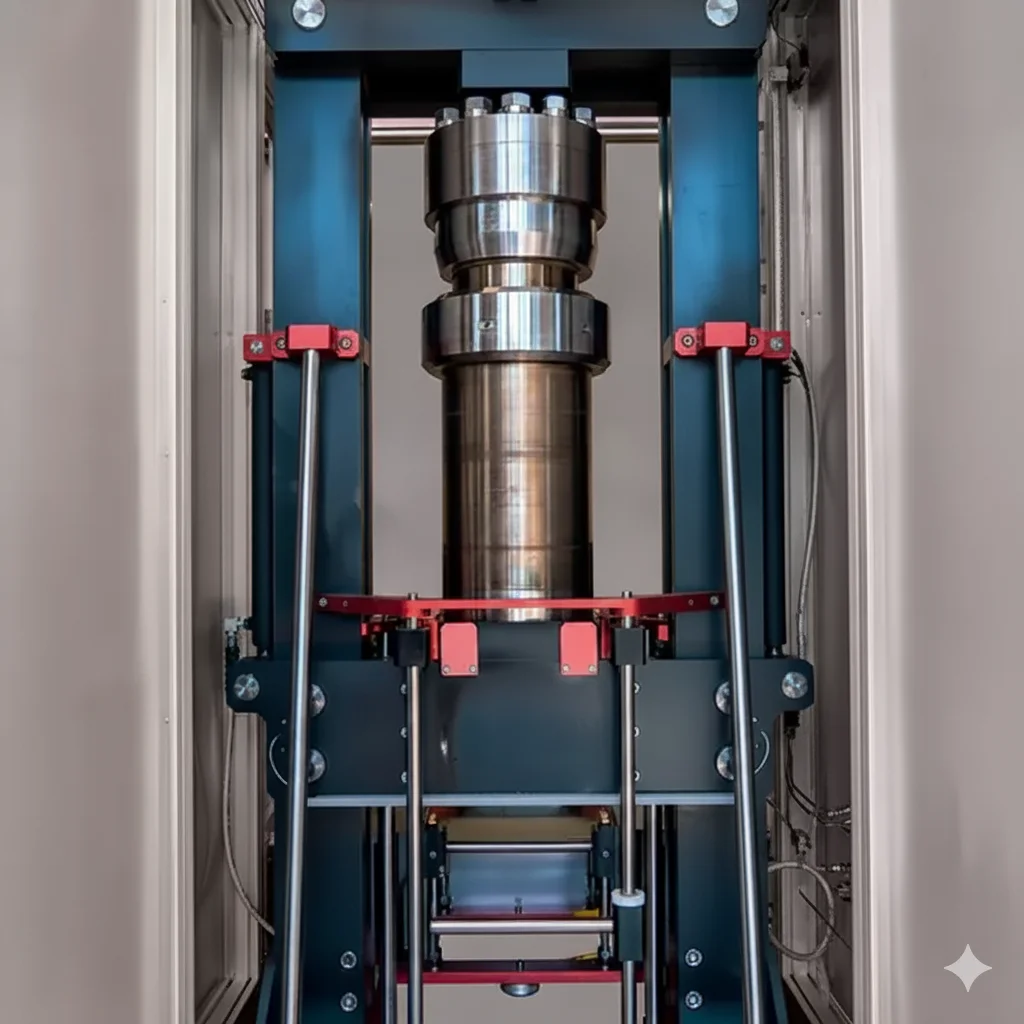

Confining Pressure (σ2 = σ3): Application of stable and controlled hydrostatic pressure, simulating lithostatic pressure. We design systems capable of reaching the pressure levels required by your application.

Axial Stress (σ1): Application of precisely controlled axial force via a loading piston, allowing the study of sample failure or deformation. The force capacity is dimensioned for your tests.

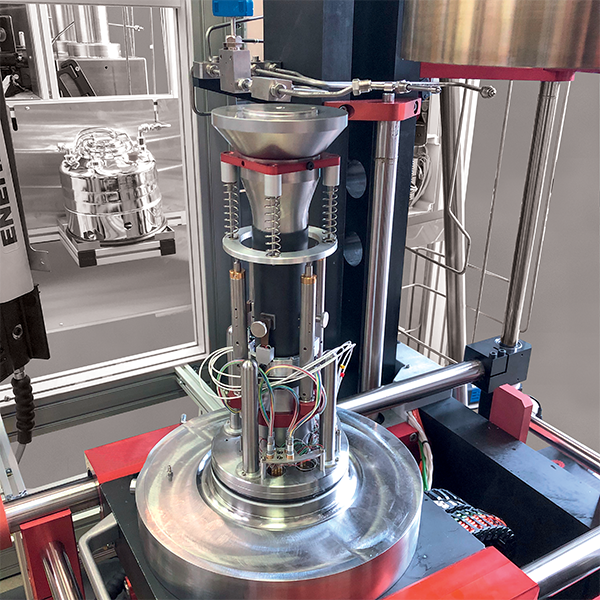

Pore Fluid Pressure: Precise injection and control of fluid pressure (water, brine, gas, oil, corrosive fluids) within the sample core to study pore pressure effects and measure permeability, at the necessary pressures.

Temperature Control: An integrated heating system maintains the sample at a homogeneous and stable temperature, suitable for your experimental conditions.

High-Precision Measurements: Integration of high-resolution sensors to measure axial force, displacements (axial and radial strain), pressures, and injected/produced volumes with the required accuracy.

Extended Chemical Compatibility: For tests involving aggressive fluids, we select the most suitable materials (specific stainless steels, Hastelloy®, Inconel®, Titanium…) to ensure durability and non-contamination.

An Essential Tool for Multiple Research Fields

Thanks to their versatility and ability to simulate extreme conditions, our custom triaxial presses are used in various fields:

Geomechanics and Petroleum Engineering…

Civil Engineering and Geotechnics…

Geological Storage (CO2, Nuclear Waste)…

Material Science…

Technical Capabilities Adaptable To Your Needs

Each IRIAN MECATRONICS triaxial system is unique. We work with you to define the specifications that perfectly match your experimental constraints:

Pressure Ranges (Confining, Pore): Defined according to your objectives, from tens to hundreds of MPa.

Maximum Axial Force: Sized to achieve the desired stresses on your samples, from a few kN to several thousand kN.

Temperature Range: From ambient to high temperatures, as needed.

Sample Size: Compatible with your laboratory standards (cylindrical, cubic, specific dimensions).

Materials (Wetted Parts): Extensive choice of stainless steels, superalloys (Hastelloy®, Inconel®), or other specific materials for optimal chemical compatibility.

Instrumentation: Selection of suitable sensors (force, displacement, pressure, temperature) with the required accuracy and resolution.

Pump Systems: Choice of technologies (volumetric, dosing) to guarantee the necessary flow or pressure stability and precision.

Control and Software: Flexible and intuitive control system (PLC + PC HMI), with options for integration into your environment (e.g., LabVIEW).