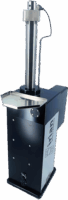

6 mL 6000 bar UHP Pump for Water Pressurization in Food Science Research

For the GEPEA laboratory (UMR – CNRS 6144) at ONIRIS Nantes, IRIAN MECATRONICS designed and manufactured an automatic Ultra High Pressure (UHP) volumetric pump. This 6000 bar (87,000 psi) system replaces an existing manual pump, providing precise PC control. The primary challenge was mastering the extreme pressure with a simple fluid (water) while ensuring absolute safety via a non-reversible mechanical architecture.

The Challenge: Mastering 6000 bar

The GEPEA food science laboratory was using a manual pump for its pressurization experiments on a 31 mL cell. To modernize this equipment and improve test repeatability, the client required an automated controlled system.

While the base parameters (Fluid: Water, Temperature: Ambient) were standard, the project presented a singular, extreme technical challenge: 6000 bar pressurization. This UHP (Ultra High Pressure) requirement transforms simple constraints into a complex engineering problem. The specifications demanded:

Extreme Pressure: Achieve and regulate an operating pressure of 6000 bar (87,000 psi).

Precise Ramps: The flow rate had to be finely controlled to generate precise pressure ramps (calculated at 35 bar/s ascent and 100 bar/s descent).

External Control: The system needed to be fully controllable by an external PC via an Ethernet (RJ45) connection.

Enhanced Safety: Replacing a manual system implied an absolute guarantee of safety at 6000 bar, especially during a potential power failure.

The Solution: A 6 mL Pump with a Non-Reversible Architecture Dictated by Pressure

To meet this extreme pressure challenge, our engineering department designed a 6 mL (minimum useful volume) volumetric pump where every design choice was dictated by the 6000 bar requirement.

IRIAN MECATRONICS’s expertise is demonstrated in these key technical choices:

Non-Reversible Drivetrain: The pump is driven by a stepper motor coupled to a worm/wheel gear and a roller screw. This architecture was deliberately chosen for two reasons:

It provides significant mechanical reduction, allowing for ultra-precise flow control (down to 0.0002 mL/min).

It is mechanically non-reversible. This is a major intrinsic safety feature: it maintains the 6000 bar pressure in the reservoir even in the event of a power failure, ensuring test integrity.

UHP Materials and Connection: To ensure mechanical integrity, the pump body, piston, and cap are machined from high-strength martensitic stainless steels (such as 15/5 PH or F6NM). The hydraulic port is an Autoclave 1/4″ UHP (F 250 C100) fitting, specifically designed for these extreme pressure levels.

Advanced Control: The system is controlled by an HMI developed in Labview, communicating via Ethernet. The interface allows programming ramps in $bar/s$ or $mL/min$, configuring up to 10 steps, and logging all data.

Does your application impose specific injection constraints?

Complex fluids, high pressure, or process integration: our engineering team sizes the system adapted to your experimental protocol.