High-Pressure Reactor 550 bar for Geoscience Research

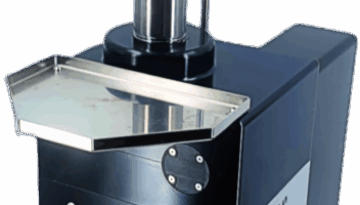

For the BRGM, we designed an HP reactor (550 bar, 250°C) made of Alloy 625. It resists the most corrosive fluids, including H₂S, for rock sample studies.

For the BRGM, we designed an HP reactor (550 bar, 250°C) made of Alloy 625. It resists the most corrosive fluids, including H₂S, for rock sample studies.

For a major energy group, we designed an HPHT test bench (140 bar, 130°C) for carbonation studies. The Hastelloy C-276 solution resists corrosive fluids (salt water, CO2).

We built 1200 bar HPHT floating piston cells (up to 5L) for reservoir fluid studies. Made of Super Duplex F53, they resist corrosive fluids (brines, CO2).

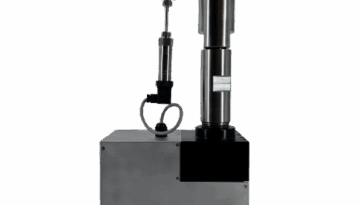

For a major energy client, we designed this 750-bar positive displacement pump. It provides precise confinement management for reservoir fluid experiments.

For a major defense industry player, we designed an automated tank cleaning system for ATEX environments. This solution improves productivity, ergonomics, and operator safety.

For IFPEN, we designed two reactors (500°C, 130 bar) for corrosion testing. The Inconel 625 solution withstands oxidizing gases at very high temperatures.

Replaced a manual pump with an automated 6000 bar / 6 mL pump for GEPEA (ONIRIS/CNRS). Features PC control and a non-reversible drive.

For TotalEnergies, we designed a portable and secure demonstrator to visualize the phase transition of supercritical CO2 during a conference.

For the BRGM, we designed an osmosis test bench. It measures tiny liquid flows (20 µL/day) through argillite samples under 50 bar confinement.

For an energy major, this HPHT pilot (50 bar) simulates turbulent flow. It measures the effectiveness of Drag Reducing Agents (DRA) without shearing them, using a custom low-shear pump.