750-Bar Positive Displacement Pump for Confinement Management in Geosciences

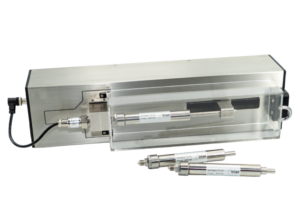

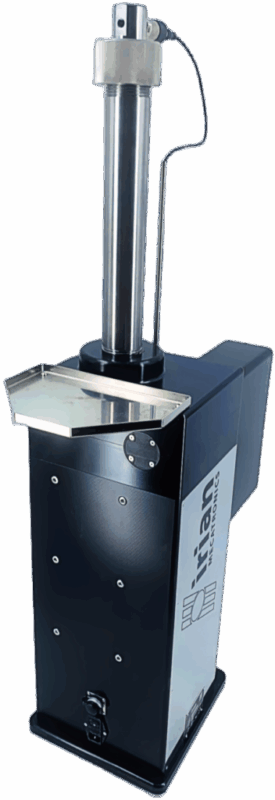

To meet the requirements of a major energy sector client, IRIAN MECATRONICS designed and manufactured a set of three high-pressure positive displacement pumps. These custom-built systems are specifically developed to provide precise confinement management during laboratory experiments on reservoir fluids.

The Challenge: Precision and Reliability for HP Reservoir Simulation

The laboratory required a system capable of reliably reproducing the high-pressure conditions found in geological reservoirs. The specifications demanded a precise and versatile solution to handle fluids under extreme constraints.

Our Solution: A Failsafe Pump Built with High-Performance Alloys

At the heart of the system is a servomotor coupled with a worm gear assembly and a roller screw drive. This design provides two major advantages: highly refined flow control through significant mechanical reduction, and a non-reversible mechanism that maintains reservoir pressure in the event of a power failure, ensuring the integrity of ongoing experiments.

Careful Material Selection: Durability under high pressure and compatibility with laboratory fluids guided material choices:

- Pump Body: Martensitic stainless steel APX4 (1.4418) was selected for its unique combination of high mechanical strength and excellent corrosion resistance.

- Piston: A Cupro-Aluminium alloy (CuAl10Ni5Fe4) ensures superior wear resistance and low friction, extending system lifespan.

- Seals: FKM O-rings, recognized for their chemical and thermal resistance, complete the assembly.

Control and Integration:

Each pump is operated through a PC-based human-machine interface (HMI) connected via Ethernet. Communication protocols include Modbus (TCP, UDP), EtherCAT, and EtherNet/IP, offering full flexibility for integration into the client’s existing laboratory environment.

Does your application impose specific injection constraints?

Complex fluids, high pressure, or process integration: our engineering team sizes the system adapted to your experimental protocol.