Custom 800 bar High-Pressure Syringe Pump in Hastelloy C-276 for CNRS-ICMCB

The Institute of Condensed Matter Chemistry of Bordeaux (ICMCB), an internationally renowned research unit associated with the CNRS, partnered with IRIAN MECATRONICS for a major scientific challenge. As part of their research on the origin of life, they needed to replicate the conditions of deep-sea hydrothermal vents, which required injecting corrosive fluids at extremely precise pressures and flow rates. We engineered and delivered two custom syringe pumps capable of operating up to 800 bar with microliter-per-minute stability.

The Challenge: Extreme Flow Stability at 800 bar with Corrosive Fluids

To simulate the natural processes occurring in deep ocean environments, the ICMCB laboratory had to overcome major technical constraints. The required equipment needed not only to achieve exceptional performance but also to guarantee complete reliability for experimental reproducibility.

The specifications outlined the following needs:

Chemical Compatibility and Corrosion Resistance: The equipment had to handle concentrated saline solutions (up to 50 g/L NaCl) and dissolved gases (CO₂, CH₄, CO, NH₃) without any degradation or contamination.

Ultra-Wide Flow Rate Range: The system needed to deliver very low flow rates for microfluidic applications (0.1 µL/min) up to much higher rates (60 mL/min).

Flow Stability and Precision: A stability of 0.05 µL/min was mandatory to ensure the validity and repeatability of scientific measurements over long periods.

Very High Pressure: To accurately simulate deep-sea conditions, the system had to reach and maintain a stable pressure of up to 800 bar.

Flexibility and Integration: The equipment had to be controllable via intuitive software and integrable with existing external control systems, such as LabView.

Technical Solution: A Custom HP Syringe Pump Combining Precision, Versatility, and Safety

The IRIAN MECATRONICS engineering team met this challenge by developing a custom solution focused on performance, robustness, and flexibility.

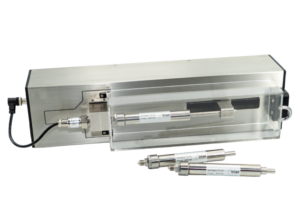

Selection of an Exceptional Material: For all wetted parts, we selected Hastelloy C-276. This high-performance alloy offers unparalleled chemical resistance to the process fluids, thereby ensuring the purity of the experiments and the maximum durability of the equipment.

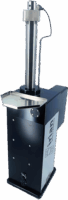

High-Precision Mechanics: The core of the system is a motorized syringe driver, engineered to generate the force required to reach 800 bar while providing fine motor control sufficient to regulate flow rates on the order of nanoliters per second.

Versatility with Interchangeable Syringes: The system was designed to accommodate syringes of different volumes (10 mL for 800 bar and 25 mL for 340 bar). This quick interchangeability offers researchers maximum flexibility to adapt the equipment to various experimental scales.

Integrated Safety: Operator safety is paramount. Each pump is equipped with a plexiglass protective cover featuring an interlock sensor that immediately stops the system and depressurizes the syringe if opened. An independent hardware safety module also prevents any risk of overpressure.

Advanced Software Control: We provided comprehensive control software for Windows while ensuring full compatibility for external control via LabView drivers, thus meeting the client’s integration needs.

Does your application impose specific injection constraints?

Complex fluids, high pressure, or process integration: our engineering team sizes the system adapted to your experimental protocol.