Frequently Asked Questions (FAQ) – All about Irian Mecatronics

Welcome to our comprehensive FAQ. We have compiled all the questions you may have about Irian Mecatronics, our unique expertise in high-pressure mechatronics, our products, services, and processes.

1. Our Identity and Our History

2. Our Expertise and Our Products

3. Our Clients and Sectors of Activity

4. Our Process and Our Services

5. Quality, Standards, and Location

6. Contacting Irian Mecatronics

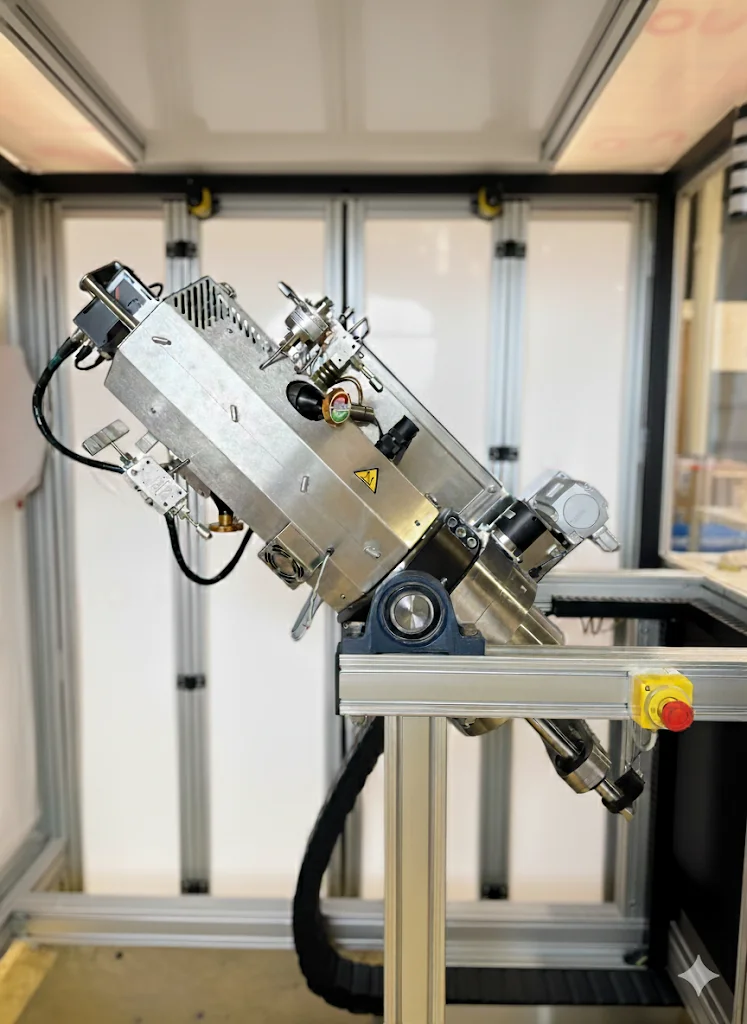

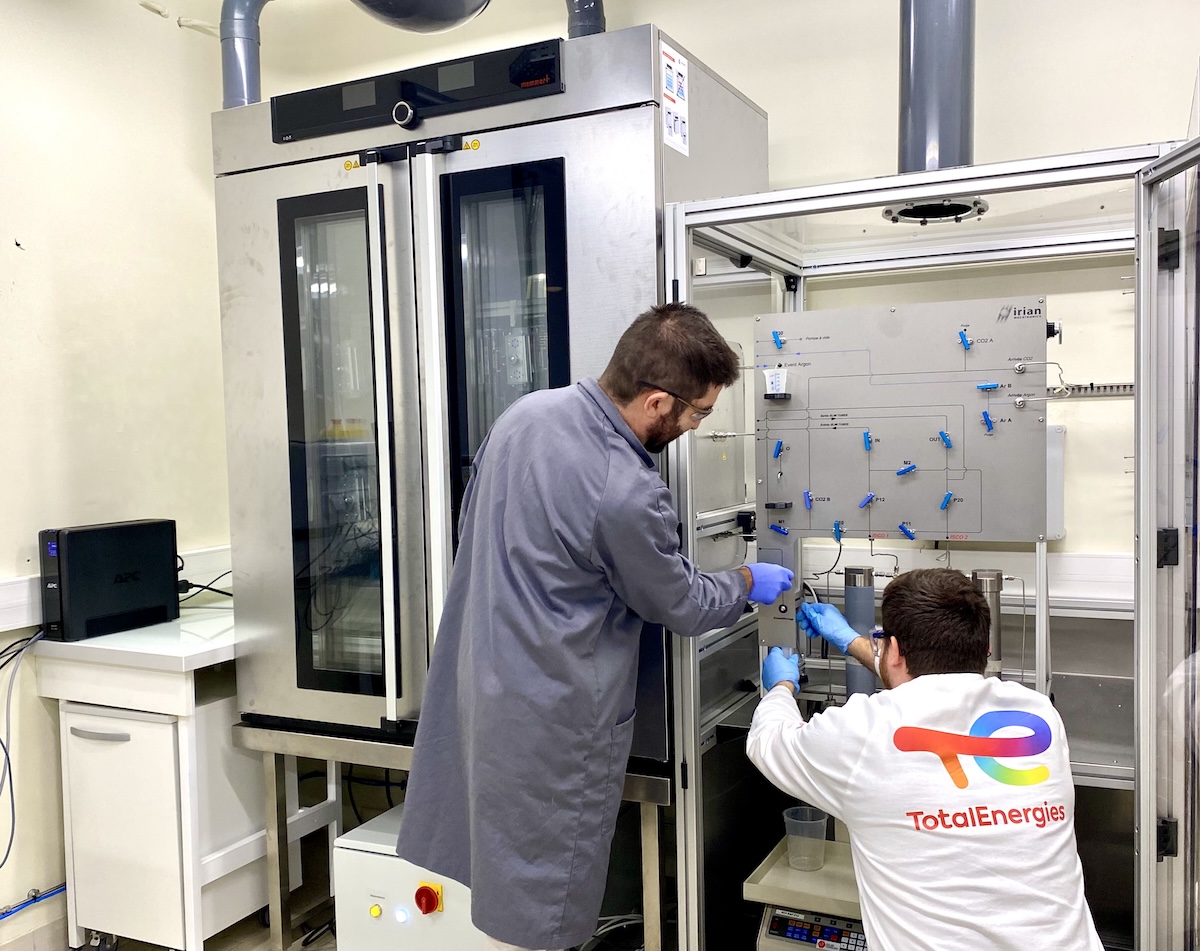

Examples of Similar Designs

R: Irian Mecatronics is a French SME (Small and Medium-sized Enterprise) specializing in the custom design and manufacturing of scientific and industrial equipment that operates under High Pressure (HP) and High Temperature (HT) conditions. We provide complete systems, from mechanical design to maintenance.

R: We noticed that when our French-speaking clients and partners read the English word “Mechatronics,” they tended to pronounce it “the French way,” which resulted in “Mé-chat-tronics” (with the /ʃa/ sound of the word “cat” in French). By choosing the spelling “Mecatronic” (without an ‘h’), we solved this problem. Our name naturally guides pronunciation to “Mé-CA-tronic,” which is not only correct but also perfectly merges our two pillars of expertise:

“Méca” (for our core business: precision mechanics and high pressure)

“Tronic” (for the electronics and control systems we integrate into it)

R: Mechatronics is an engineering discipline that combines mechanics, electronics, automation, and computer science. For us, this means we don’t just deliver a “machine”; we deliver a complete, functional system where precision mechanics are perfectly integrated with sensors, actuators, and control software.

R: Irian Mecatronics was born from the strategic merger of two historic areas of expertise:

ACEI Services: Renowned expertise spanning nearly 30 years in the service, maintenance, and retrofitting of laboratory equipment.

Sanchez Advance Technologies: A pioneering design office and globally recognized specialist in the manufacturing of PVT (Pressure, Volume, Temperature) cells.

This union, finalized in 2022, created a unique entity capable of designing, manufacturing, AND maintaining high-complexity HP/HT systems.

R: We regularly work with very wide pressure and temperature ranges that far exceed industrial standards. Although each project is unique, we have the experience to design systems capable of reaching several thousand bar and several hundred degrees Celsius, depending on the fluids and materials involved.

R: Our production is mainly focused on custom-built solutions. Our main product families include:

Custom Test Benches & Testing Systems

Reactors & Autoclaves (Pilot or Laboratory scale)

PVT (Pressure, Volume, Temperature) Cells

High-Pressure Syringe Pumps

Triaxial Test Systems (for geomechanics)

R: It is a system specifically designed for a client to test, validate, or qualify a component, material, or process. Our test benches can be used, for example, for:

Corrosion testing (H2S, CO2…)

Validation of components for hydrogen storage

Study of CO2 capture and storage (CCS)

Study of reservoir fluids (petrophysics)

Accelerated aging tests

Fatigue or resistance testing for aeronautics

Geothermal studies

R: A PVT Cell is a high-precision laboratory instrument used to analyze the thermodynamic behavior (phase changes, density, compressibility) of a fluid by varying Pressure, Volume, and Temperature. It is a specialty (inherited from Sanchez Advance Technologies) because its design requires extreme mechanical and metrological mastery to guarantee reliable measurements under extreme conditions.

R: Our clients are demanding players who push the boundaries of science and technology. They are typically:

Public research laboratories (Universities, CNRS…)

Private industrial R&D centers

Process engineers and production managers

Scientists and researchers

R: Our HP/HT expertise is crucial in many sectors:

Energy, Oil & Gas, and Energy Transition

Petrophysics & Core Analysis: Test benches for studying geological cores, permeability analysis, and reservoir fluid behavior (PVT).

Well Testing & Cementing: Systems to simulate and validate the integrity of cement and downhole equipment.

HP/HT Corrosion: Autoclave test benches for testing material resistance in aggressive environments (H2S, supercritical CO2, brines).

New Energies (Hydrogen, CO2):

Component validation for hydrogen storage (materials compatibility, leak testing, pressure cycling).

Studies on CO2 capture and storage (CCS) under supercritical conditions.

Pilot test benches for methanation or gasification.

Geosciences and Rock Mechanics

Geomechanics: Design of triaxial test benches to study rock strength under stress and high temperature.

Marine Geosciences & Biology: Systems to simulate deep-sea (abyssal) pressures for studying ecosystems or subsea equipment.

Chemistry, Processes, and Materials

Pilot Reactors: Units for the study and optimization of chemical processes (e.g., catalysis, polymer synthesis).

Supercritical Fluids: Complete equipment for extraction, purification, or reaction using fluids like CO2 or H2O in a supercritical state.

Materials Test Benches:

Accelerated aging tests on polymers, composites, or elastomers.

Fatigue or mechanical resistance tests (creep, burst) for Aeronautics or Defense.

Fundamental Research and UHP

Thermodynamics: Benches for studying phase equilibria and fluid properties at HP/HT.

Ultra High Pressure (UHP): Specific systems like “Gas Loaders” for charging diamond anvil cells (DAC) used in fundamental research.

Specific Applications: We also design benches for sectors like Cosmetics (supercritical extraction) or Defense (ballistic tests, pyrotechnics).

R: We follow a rigorous process, in collaboration with the client:

Needs Analysis: Understanding your scientific or industrial objectives.

Specifications: Definition of technical specifications (pressure, temperature, fluids…).

Design & Engineering: Our design office models the solution (3D drawings, strength calculations).

Manufacturing & Assembly: Carried out in our workshops.

Tests & Validation (FAT): We test the equipment at our factory before shipment (FAT = Factory Acceptance Test).

Installation & Commissioning (SAT): Installation at your site and training for your teams (SAT = Site Acceptance Test).

Support & Maintenance.

R: Yes. Maintenance is at the core of our DNA (ACEI Services heritage). We offer preventive maintenance contracts (to prevent breakdowns) and curative maintenance (rapid intervention in case of a problem), available on-site or remotely.

R: Retrofitting (or upgrading) consists of modernizing existing equipment. If you have a test bench or reactor that has become obsolete (mechanically or in terms of its control system), we can modernize it: adding new sensors, software updates, component replacement, and safety compliance upgrades.

R: Yes. Thanks to our long experience in multi-brand maintenance, our technicians are qualified to work on a wide variety of laboratory and pilot equipment, even if it was not manufactured by Irian Mecatronics.

R: Safety and quality are our absolute priorities.

We are ISO 9001 certified for our quality management system.

All our pressurized equipment is designed in strict compliance with the European Pressure Equipment Directive (PED 2014/68/EU).

We can also design equipment compliant with other standards upon request (ATEX, ASME, etc.).

R: We have two sites in France to better serve our clients:

Moissac (82200, Occitanie): Headquarters and administrative hub.

Morlaàs (64160, Nouvelle-Aquitaine): Our main technical center, design office, and production workshop.

R: Yes. Our expertise is recognized worldwide. We deliver, install, and maintain our equipment for clients and laboratories on every continent.

R: The easiest way is to contact us via the form on our website or by phone. Please prepare a description of your needs (fluids, pressure, temperature, objective) and our team of engineers will contact you for an in-depth technical analysis.