Precision Pumps & Injection Systems for Research and Industry

IRIAN MECATRONICS designs and manufactures high-pressure pumps and injection systems for controlling fluids under high pressure. Our systems are engineered to meet the requirements of the most demanding research and industrial applications.

We offer a range of standard equipment, which can serve as a basis for specific adaptations, as well as fully custom designs to meet your exact specifications.

Technical Capabilities & System Design

Our approach is centered on robust engineering and providing the right level of customization to meet specific experimental parameters and budgets.

- Flexible Engineering Approach: We offer several paths to your ideal solution:

- Standard Range: A selection of pre-engineered pump models for common high-pressure applications, providing proven performance and reliability.

- Adapted Standard Models: We can modify our standard pumps with different wetted materials, seal options, volumes, or control features. This provides a cost-effective way to get a tailored system that is closely based on a standard design.

- Fully Custom Systems: For unique challenges, our engineers will design a pump system from the ground up to meet your exact process or experimental parameters.

- Repeatable and Stable Flow Control: Our pumps provide highly stable, pulse-free flow, crucial for long-duration experiments where parameters must remain constant. The system can be configured for either constant flow rate or constant pressure control, delivering exceptional accuracy for metering pump and dosing applications.

- High Pressure & High Temperature (HPHT) Operation: We design systems capable of operating under extreme conditions, including pressures up to 6000 bars and elevated temperatures, allowing for the replication of true environmental or process conditions.

- Material Selection for Fluid Compatibility: System integrity is paramount. We select all wetted parts based on your fluid’s properties. Our expertise covers a range of materials, including various grades of Stainless Steel, Hastelloy, and Titanium, ensuring compatibility with corrosive fluids, brines, and gases like H2S or SCCO2.

Automation and Data Logging: Our automated syringe pump systems are controlled via dedicated software, allowing for the programming of complex injection sequences, cyclic loading, and the logging of all critical data (pressure, volume, flow rate) for analysis.

A Versatile Tool for Advanced Research & Process Control

Our syringe pumps are designed for critical applications where flow stability, pulse-free delivery, and volumetric accuracy are essential parameters, even under very high pressures and temperatures.

They are primarily integrated into test benches for the following fields:

Geosciences and Reservoir Engineering

Enhanced Oil Recovery (EOR) studies, core flooding tests, permeability measurements, and PVT (Pressure-Volume-Temperature) analysis of reservoir fluids.Fine Chemistry and Process Development

Continuous and stable feeding of high-pressure reactors, catalyst evaluation, and polymerization studies under extreme conditions (up to 6000 bar / 200°C).Complex Fluid Dosing

Precise injection of supercritical fluids (e.g., CO2), liquefied gases, or aggressive fluids (brines, H2S, acids) through a selection of adapted materials (e.g., Hastelloy C276, Titanium).Instrumentation and Fundamental Research

Integration as a pressure or flow generation module in custom test benches.

More Than a Component: A Partnership in Engineering

For us, a pump is often the starting point of a larger engineering challenge. While we supply standalone pump systems, our core expertise lies in their integration into complete, custom-designed experimental apparatus.

A high-pressure pump from Irian Mecatronics is your entry point to our broader capabilities in designing and manufacturing reactors, test benches, and fully integrated high-pressure systems. We understand that your experiment is more than just a pump; it’s a complex system where every component matters.

FAQ

Our Injection System Project Examples

500 bar / 150°C Titanium Variable Volume Cell for HP Fluid Research

50 mL / 500 bar Titanium variable volume cell. Features magnetic stirring, safety worm gear drive, and double-flange sapphire.

300 bar Precision Pumps for Microgravity Research (SCWO)

300 bar pump & regulation modules for SCWO experiment in microgravity (ISS). Manages reactive fluids (H2O2) & microflows (µL/min).

2L / 15 bar Volumetric Pump for 98% Sulfuric Acid Injection

2L / 15 bar volumetric pump for 98% sulfuric acid (H₂SO₄) injection. Expertise in Super Duplex and FKM materials.

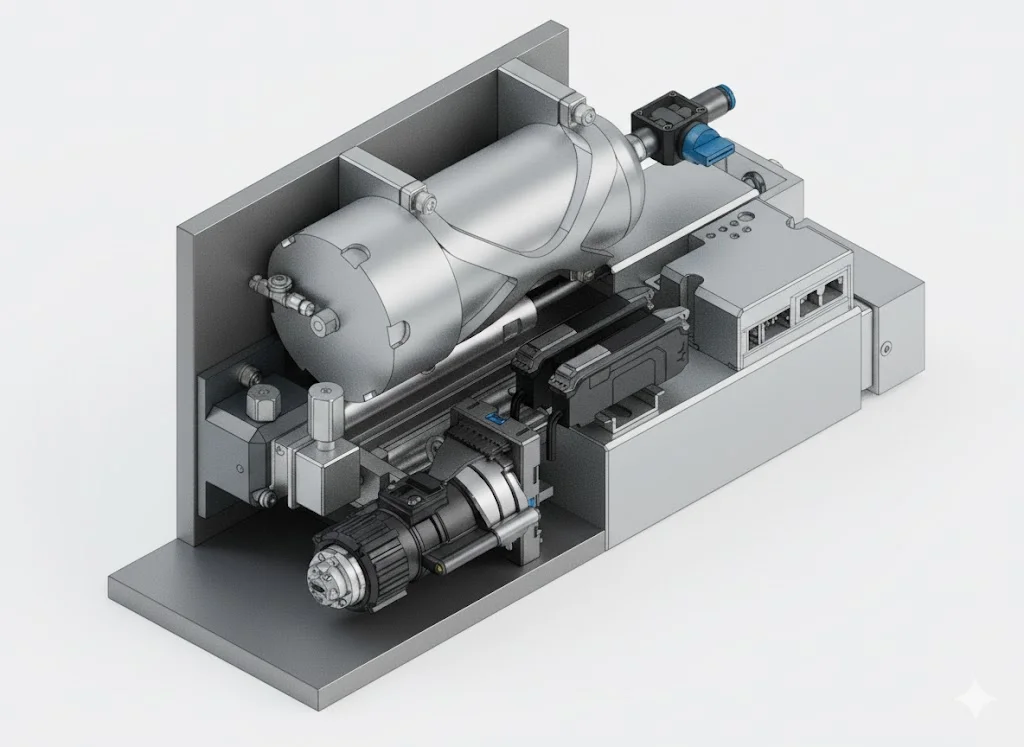

750-Bar Positive Displacement Pump for Confinement Management in Geosciences

For a major energy client, we designed this 750-bar positive displacement pump. It provides precise confinement management for reservoir fluid experiments.

6 mL 6000 bar UHP Pump for Water Pressurization in Food Science Research

Replaced a manual pump with an automated 6000 bar / 6 mL pump for GEPEA (ONIRIS/CNRS). Features PC control and a non-reversible drive.

12CC 600 bar Volumetric Pump for Pressure Control in Corrosive Media (Na2S) for CNRS

For the CNRS (Bacterial Chemistry Lab), we designed this 600 bar pump. It provides precise pressure regulation for a 500 µL observation cell.

Pump refurbishment: high-pressure positive displacement pumps

We carried out a complete refurbishment of two HP positive displacement pumps. The project included mechanical overhaul and modernization of the automation and user interface.

Custom Dual-Piston Injection Pump for Mixing Complex Industrial Fluids

For a manufacturing leader, we designed a dual volumetric pump (200 bar) for the precision mixing of reactive fluids (polymer, abrasive suspensions).

Custom 800 bar High-Pressure Syringe Pump in Hastelloy C-276 for Origin-of-Life Research

For the ICMCB (CNRS), we designed these 800 bar syringe pumps in Hastelloy. They simulate hydrothermal vents by injecting corrosive fluids with extreme stability.

Water Meter Test Bench: Automated Dual Syringe Pump for Wide Flow Ranges

Dual syringe pump test bench for Sagemcom. Flow range from 1 to 5500 L/h, active thermal regulation, and high metrological precision.

Does your application impose specific injection constraints?

Complex fluids, high pressure, or process integration: our engineering team sizes the system adapted to your experimental protocol.