12CC 600 bar Volumetric Pump for Pressure Control in Corrosive Media (Na2S) for CNRS

For France’s National Centre for Scientific Research (CNRS) in Marseille , IRIAN MECATRONICS designed a 12CC 600 bar high-precision volumetric pump. The objective was to enable pressure regulation on a very low-volume (500µl) observation cell while ensuring perfect compatibility with corrosive fluids (salt water, Na2S). Our solution is a PC-controlled SS316 system , featuring a double jacket for temperature control and a non-reversible mechanical architecture for enhanced safety.

The Challenge: 600 bar Pressure Regulation on a Micro-Volume with Corrosive Fluids

The CNRS laboratory required a system capable of generating and regulating a 600 bar pressure with extreme stability within a very small experimental volume of 500µl.

The project presented multiple critical technical constraints:

Chemical Compatibility: The system had to be fully compatible with corrosive working fluids, specifically salt water and Na2S (Sodium Sulfide).

Temperature Control: The pump needed to integrate a double jacket to allow for fluid temperature regulation from 0°C to ambient temperature via an external thermostatic bath.

Low Dead Volume: To work with a 500µl cell, the hydraulic connections needed to be zero dead volume (VALCO fitting for 1/16″ tubing).

Ease of Cleaning: The design had to allow for quick disassembly for a complete internal cleaning of the reservoir.

Specific Use-Case: The equipment had to allow the wetted parts (cylinder, piston, cap) to be filled in a glove box before being connected to the pump drive.

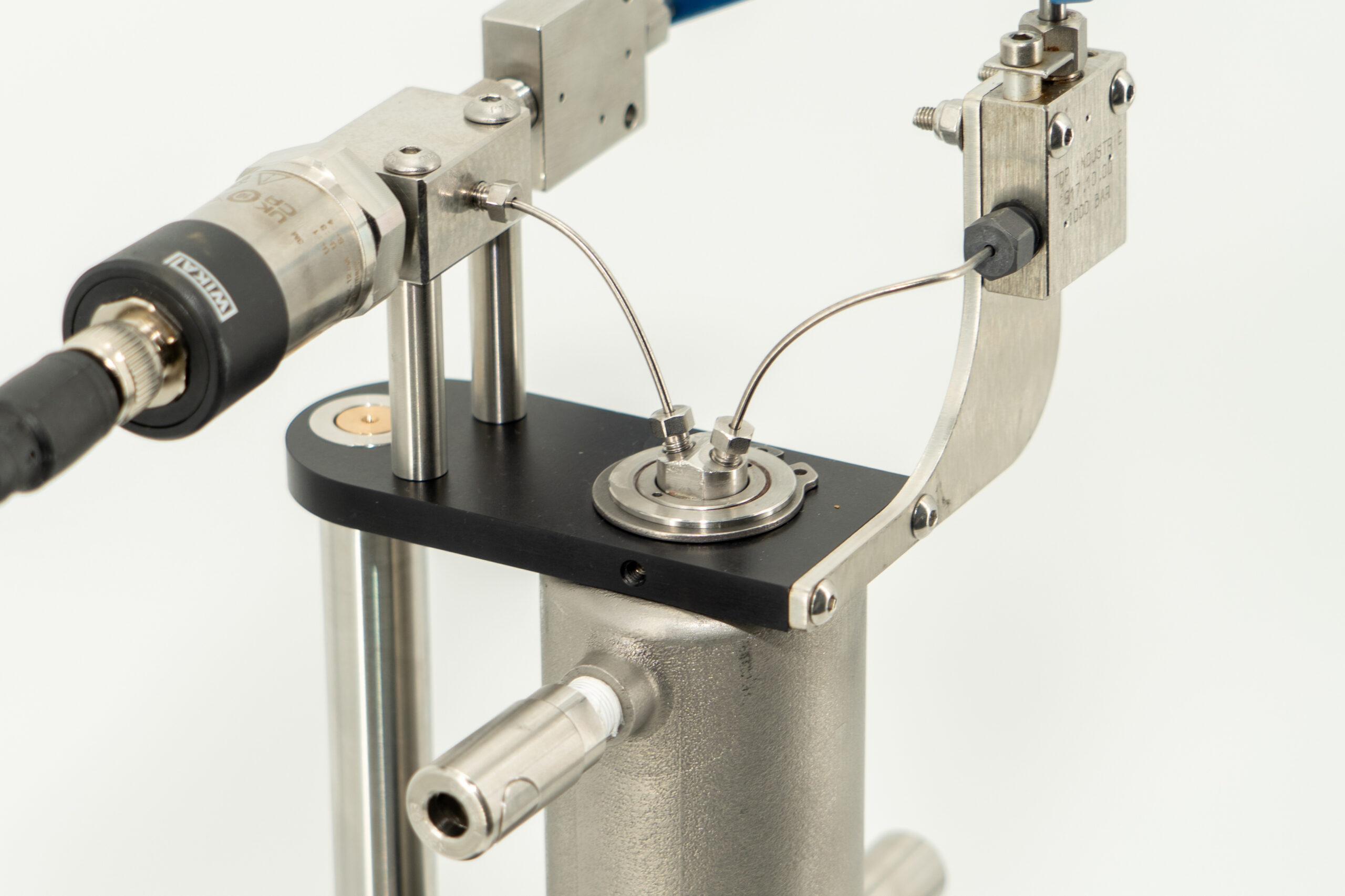

The Solution: A 12CC SS316 Pump with Non-Reversible Architecture and PC Control

To meet these specifications, our design office engineered a 12CC volumetric pump where every component was designed for precision and safety.

The IRIAN MECATRONICS technical solution is based on:

A Secure Mechanical Architecture: We chose a worm/wheel gear and ball screw drive system. This technical choice offers a dual advantage: significant mechanical reduction, allowing for a very wide flow rate range (from 0.002 cc/min to 15 cc/min ), and intrinsic safety. The system is non-reversible, which guarantees the 600 bar pressure is held in the circuit even during a power failure.

Adapted Materials: To ensure compatibility with salt water and Na2S , all wetted parts (pump body, piston, cap) were machined from 316 stainless steel.

Design for Maintenance: As shown in the schematics, the pump features a quick-disassembly reservoir cap. This design facilitates cleaning and allows for glove box filling.

Comprehensive Software Control: The system is controlled by a remote PC via an RJ45 connection. The software allows operation in flow rate setpoint or pressure setpoint (with ramp) modes and handles data acquisition.

Does your application impose specific injection constraints?

Complex fluids, high pressure, or process integration: our engineering team sizes the system adapted to your experimental protocol.