Extreme Environment Simulation Systems / Geoscience & Subsurface Studies / Test Benches & Experimental Pilot Units

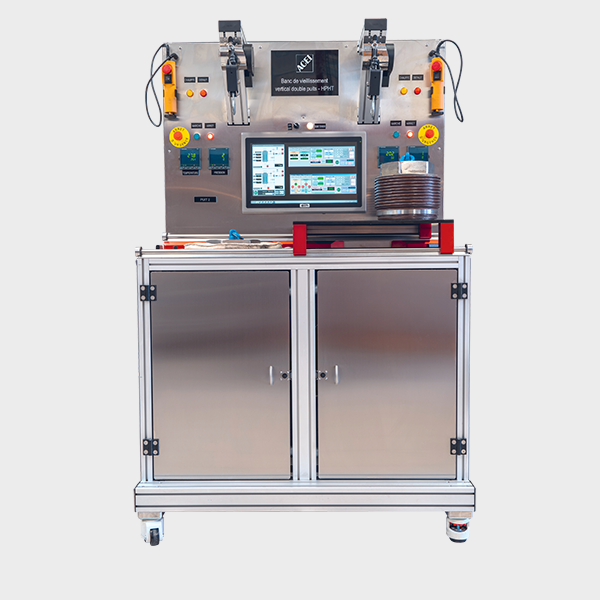

1380 bar HPHT Aging Bench: Simulating Extreme Conditions for Cement and Fluids

For a major player in the energy sector (Fluids & Cements Department), IRIAN MECATRONICS developed a testing solution capable of simulating downhole conditions over extended periods. The challenge was to maintain extreme pressure and temperature conditions autonomously and safely. We designed a turnkey dual-well aging bench combining regulation precision with operational ergonomics.

Challenges of Long-Duration Simulation in Geosciences

Validating fluid and cement formulations for the industry requires faithfully reproducing geological constraints, often over prolonged periods. For this project, the client laboratory faced several critical requirements:

Extreme and Stable Conditions: The need to reach and maintain a working pressure of 1380 bar (20,000 PSI) and a temperature of 300°C without fluctuation.

Productivity and Parallelization: The requirement to test two samples simultaneously but with independent regulation parameters to optimize research campaigns.

Operational Safety: Managing aging tests implies operation without constant human supervision. Equipment safety against overpressure or thermal runaway is therefore a non-negotiable prerequisite.

HPHT Design: Passive Safety and Advanced Ergonomics

Rather than offering a simple autoclave, IRIAN MECATRONICS designed a complete workstation where every technical choice aims to facilitate the researchers’ daily tasks while ensuring test integrity.

Hybrid Regulation Architecture: To ensure perfect stability at 1380 bar, we opted for pressure regulation via syringe pumps coupled with back pressure valves. This choice allows for ultra-fine compensation of volume variations due to temperature, ensuring that the setpoint pressure remains fixed throughout the aging cycle.

“Zero Effort” Ergonomics: High-pressure cell plugs are traditionally heavy and difficult to handle. We integrated a secure opening system using counterweights. This eliminates the need for hoists or external lifting tools, reducing physical strain for operators and the risk of mishandling during frequent loading.

Homogeneous Thermal Management: Beyond heating, controlling the temperature ramp-down is crucial to freeze material states. The integration of a “double cooling” system in each well ensures rapid and homogeneous cooling, allowing for more reliable post-test analysis.

Autonomy and Connectivity: The system offers total flexibility thanks to a dual control mode: autonomous via an integrated touch Panel PC for immediate lab use, or remotely controllable via external PC for integration into broader supervision protocols.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.