300 bar Precision Pumps for Microgravity Research (SCWO)

For a client in the space research sector , IRIAN MECATRONICS designed precision pumping and pressure regulation modules for a Super Critical Water Oxidation (SCWO) experiment. The primary challenge was to manage reactive fluids, including hydrogen peroxide , at 300 bar with microliter-scale flow rates , all within a microgravity environment. Our solution is based on ultra-compact modules integrating high-precision volumetric pumps and bladder-style reservoirs.

The Challenge: Ensuring Stable Microflow at 300 bar in Microgravity

The client’s objective was to feed an experimental reactor under a unique combination of extreme performance and environmental constraints. The specifications demanded absolute reliability on several critical points:

Complex Fluids: Simultaneous management of water, 70% ethanol, and 30% hydrogen peroxide, a powerful oxidizer.

Hydraulic Performance: Ensuring pressure control from 0 to 300 bar while maintaining extremely low and stable flow rates, from 2 mu L/min to 3 mL/min.

“Zero-G” Environment: The entire assembly must operate in microgravity, in any orientation, and withstand the constraints of a space launch (to the ISS).

Scientific Integrity: The architecture had to minimize dead volumes and prevent any gas trapping, which is critical for experimental accuracy.

Compactness: The equipment had to occupy the smallest possible volume.

The IRIAN MECATRONICS Approach: Functional Modules for Absolute Reliability

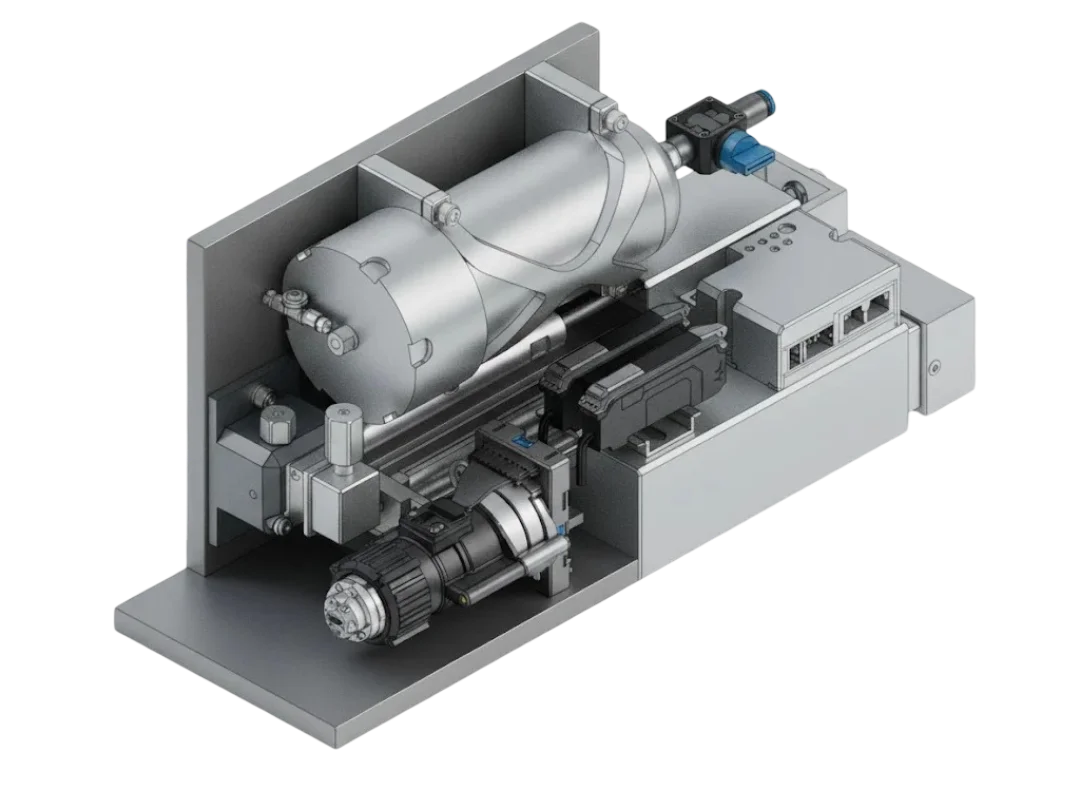

Our engineering team designed a two-part solution: a compact module (360x125x165 mm) integrating the pump, reservoir, and valve, and a separate module for pressure regulation. The design was dictated by the constraints of microgravity and precision.

Fluid Management in Microgravity. To ensure a reliable supply without gravity, the solution relies on a 200 mL bladder reservoir. Pre-charged with gas (Nitrogen or air), the bladder keeps the fluid under pressure and guarantees a positive, constant feed to the pump, regardless of the system’s orientation.

Microflow Precision. To achieve stable, microliter-scale flows (down to $2~\mu L/min$) under 300 bar, the volumetric pump is driven by a high-precision ball screw and a stepper motor. This mechanical architecture provides precise positional control, minimal internal play, and exceptional repeatability (±0.1 µL), ensuring the accuracy required by the scientific protocol.

Circuit Integrity and Safety. The minimal dead volume requirement is met by integrating “in-line” pressure sensors and compact rotary valves. This design eliminates gas trapping zones, which are critical for the experiment. Safety is guaranteed by an active downstream back-pressure regulator, supplemented by two passive relief valves set at 110% of the maximum pressure.

Does your application impose specific injection constraints?

Complex fluids, high pressure, or process integration: our engineering team sizes the system adapted to your experimental protocol.