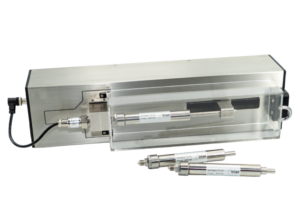

500 bar / 150°C Titanium Variable Volume Cell for HP Fluid Research

For a major chemistry research center, IRIAN MECATRONICS designed a 50 mL high-pressure variable volume cell. The challenge was to combine a 500 bar pressure rating, a 3°C to 150°C temperature range, and full CO2 compatibility within a compact Titanium body. We responded by adapting a proven mechanical design to integrate internal stirring and a visualization window, creating a versatile and robust research tool.

The Challenge: Miniaturization, Agitation, and High Pressure in Titanium

The laboratory’s request called for a precision experimental tool to study fluids under HPHT conditions. The design constraints were multiple and interdependent:

Operating Pressure: 500 bar.

Temperature Range: 3°C to 150°C (via a thermal fluid jacket).

Material: Titanium body, due to its high corrosion resistance, especially with CO2.

Volume: 50 mL.

Functionality: Integration of internal stirring and a sapphire visualization window was mandatory.

The primary engineering challenge was to fit all these functions (motorized piston, magnetic stirrer, sapphire window, 1/16″ ports) into a compact 50 mL Titanium body, a material that is notoriously complex to machine.

Our Solution: Proven Design, Ergonomics, and Intrinsic Safety

Rather than starting from scratch, our design office leveraged our existing “design bricks.” We adapted the proven mechanical design of our high-pressure pumps to create a custom research cell, focusing on reliability and ease of use.

Safety and Stability: The Non-Reversible Drive Volume control is managed by a worm gear drive. This mechanism is mechanically non-reversible. The user benefit is twofold: high precision in flow regulation (down to 1 µL/min) and, most importantly, the static holding of pressure in the event of a power failure. The sample and equipment are thus secured, even during an electrical outage.

Simplified Maintenance: The Double-Flange Sapphire A sapphire window is installed at the end of the cell for observation. Aware of the maintenance difficulties on HP seals, we mounted it in a double-flange system. This design allows the operator to access the cell’s interior for cleaning without ever disassembling the sapphire from its HP sealing flange. This radically simplifies maintenance and preserves the integrity of the most critical seal.

Functional Integration: Titanium and Stirring To ensure compatibility with CO2 and other corrosive fluids, all wetted metal parts are made of Titanium Ti-6Al-4V ELI (Grade 23). This material provides excellent chemical and mechanical resistance . Stirring is achieved via a magnetic drive with a remote motor. The stirrer is housed inside the piston itself, which avoids the use of dynamic rotating seals and eliminates the associated leak risks.

Does your application impose specific injection constraints?

Complex fluids, high pressure, or process integration: our engineering team sizes the system adapted to your experimental protocol.