Precision Pumps & Injection Systems / Process Development & Chemical Pilot Plants / Test Benches & Experimental Pilot Units

Custom Dual-Piston Injection Pump for Mixing Complex Industrial Fluids

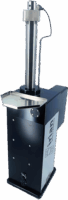

A leader in the manufacturing industry called on IRIAN MECATRONICS to develop R&D equipment capable of mixing two highly reactive fluids with extreme precision: a natural polymer and a suspension loaded with abrasive particles. Our engineering department designed and built a skid-mounted dual volumetric injection pump, ensuring perfect control of flow rates at pressures up to 200 bar, while preventing premature product degradation.

The Challenge: Mastering an Unstable, High-Pressure Mixture

To innovate its processes, our client needed a pilot system capable of dosing and mixing two components with radically different physical and chemical properties. The specifications imposed strict technical constraints to ensure the repeatability and reliability of laboratory tests.

- Complex Fluid Management: The first product, a natural polymer, had a strong tendency to degrade under mechanical shear, creating blockages. The second, an abrasive suspension, is a shear-thinning product with variable viscosity.

- Dosing Accuracy: The system had to guarantee high-precision flow control over a wide operating range for each fluid.

- High-Pressure Requirements: The pump had to reach a maximum pressure of 200 bar for the most demanding circuit, with very rapid stabilization of the operating speed.

- Material Constraints: The equipment had to be designed to avoid any shear and turbulence zones. The use of stainless steel was imperative for all parts in contact with the products to prevent corrosion and contamination.

- Ergonomics and Safety: The entire unit had to be mounted on a mobile skid, accessible from the front for filling, operation, and maintenance, while integrating safety systems suitable for high pressures.

IRIAN MECATRONICS’ Technical Solution: A Synchronized Dual Pump Design

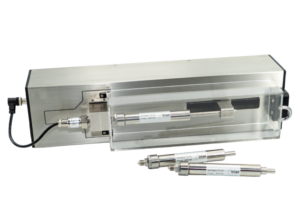

Faced with these challenges, our team developed a custom solution focused on reliability and precision. The heart of the system is a dual injection syringe,Precision Pumps & Injection Systems for Research and Industry 100% identical, driven by independent but synchronizable pistons.

The design was conceived to meet the client’s requirements point by point. To counter the risk of polymer degradation, the entire hydraulic circuit, from the pump bodies to the fittings, was designed with smooth geometries, without abrupt changes in diameter, ensuring a perfectly laminar flow. The choice of 316L stainless steel for the circuits guarantees full chemical compatibility and prevents any pollution.

The motorization of each piston allows for independent and synchronized speed adjustment, offering total flexibility for testing. Special care was taken with the filling interface, featuring a quick-release lid for easy loading of the products, whether liquid or paste-like. Mounted on a robust skid, the equipment integrates the control cabinet and a splash guard, ensuring simple and safe use for R&D operators.

Does your application impose specific injection constraints?

Complex fluids, high pressure, or process integration: our engineering team sizes the system adapted to your experimental protocol.