Geoscience & Subsurface Studies / Test Benches & Experimental Pilot Units

Design of a 3-in-1 Uniaxial Tester (CUT) for Petroleum Rock Characterization

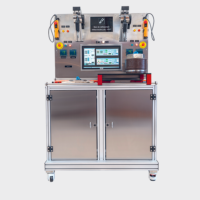

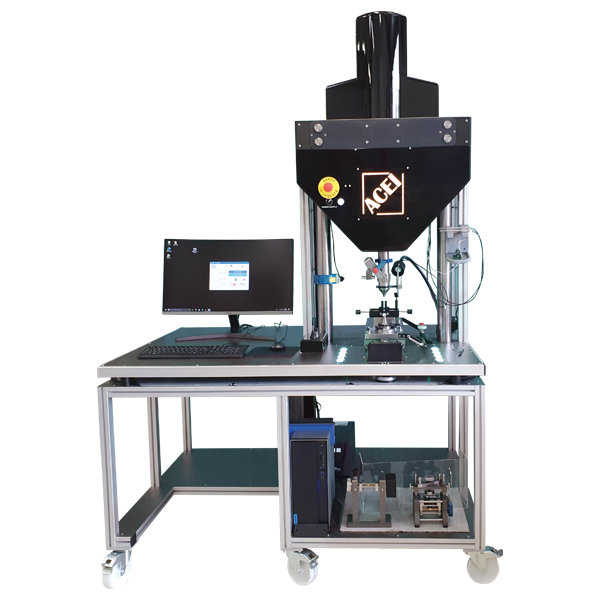

On behalf of the laboratory division of SONATRACH, IRIAN MECATRONICS designed and manufactured a high-precision mechanical testing equipment. The solution, the “Combined UniAxial Tester” (CUT) , is a 3-in-1 servo-electric press designed to optimize the characterization operations of petroleum rock samples in a laboratory setting.

The Challenge: Combining Fracture Toughness, UCS, and Bending Tests in a Single Compact Frame

Our client’s research laboratory needed to perform three distinct and fundamental types of mechanical tests for rock characterization. Historically, this required three different machines, occupying valuable space and complicating the workflow.

The challenge was to centralize these three tests onto a single frame while meeting R&D-grade precision and performance requirements.

The technical constraints were as follows:

3-in-1 Versatility: Integrate Uniaxial Compression (UCS), 3-Point Bending , and Tensile (for fracture toughness) tests into one device.

Load Capacity: Achieve a maximum load of 20 kN , applicable in both compression and tension.

High Resolution: Guarantee a force measurement resolution of 0.1 N.

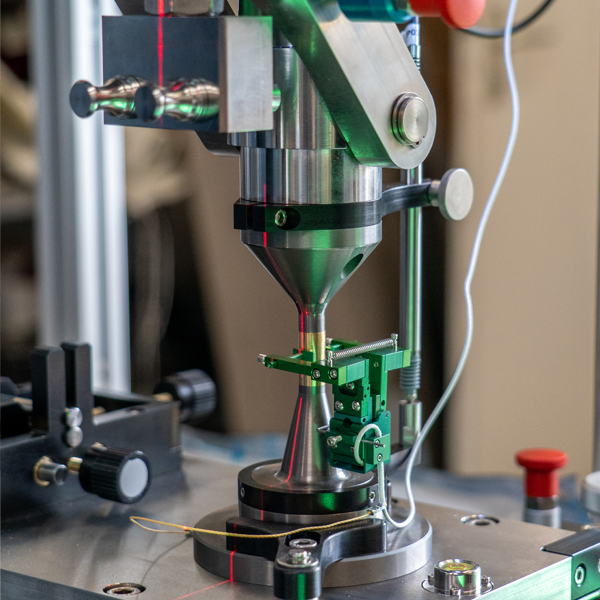

Displacement Accuracy: Required axial measurement by LVDT with 0.001 mm resolution and a radial measurement system with 0.0001 mm resolution to accurately determine the modulus of elasticity and Poisson’s ratio.

Ergonomics and Efficiency: Allow for simple, rapid, and reliable changeover between test types.

Complete Solution: Provide all auxiliary tooling, including for sample preparation (e.g., cutting artificial fissures and gluing jaws ).

The Solution: A Servo-Electric Press with a 3-Position Indexed Mobile Table

To meet this demanding set of specifications, our engineering department designed a custom mechatronic solution built around a single servo-electric loading press.

The primary innovation lies in the design of a manual mobile table. This table, which groups all three test setups (UCS, Bending, and Traction) , is mounted on pre-loaded guide rails and 6 carriages. This architecture ensures fluid movement and absolute rigidity during tests.

The operator can thus, after unlocking the carriage, manually move the assembly to position the desired tooling under the loading actuator. A precision mechanical indexing system ensures perfect and repeatable alignment for every test.

This design provides:

Space Optimization: Three test benches are consolidated into one.

A Single Load Source: A single 20 kN servo-electric actuator and a single force sensor drive all three tests, ensuring measurement consistency.

Full Integration: The system integrates all required sensors (axial LVDTs and radial extensometer ) as well as dedicated SCADA software for control, acquisition, and automatic rupture detection.

IRIAN MECATRONICS also supplied the specific preparation tooling, notably a tilting vise for cutting chevron notches on a wire saw and a gluing jig for preparing tensile samples.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.