Geoscience & Subsurface Studies / Test Benches & Experimental Pilot Units

High-Precision Osmosis Test Bench for Argillite Studies

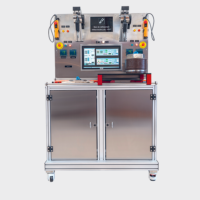

The French Geological Survey (BRGM) called on IRIAN MECATRONICS’ expertise to develop a test bench capable of measuring extremely low liquid flows through argillite samples with ultra-high precision. Our engineering department designed and manufactured a custom piece of equipment to simulate in-situ conditions and provide reliable data for geoscience research.

The Technical Challenge: Measuring Micro-Flows for Geoscience Research

The BRGM required an experimental setup to conduct osmosis tests on clay-rich rocks. The main challenge was to quantify extremely small volume displacements, in the order of 20 mg/day. The specifications demanded precise technical constraints to ensure the relevance of the results:

- Sample: Argillite with specific dimensions (Ø 40 mm x 10 mm).

- Measurement Accuracy: Ability to detect and measure liquid flows of around 20 microliters per day.

- Confining Conditions: Application of an isostatic confining pressure up to 50 bar on the sample.

- Temperature Management: Temperature control up to 40°C with the ability to create precise thermal gradients across the sample.

- Fluids: Use of water as the fluid in contact with the rock.

The primary difficulty was finding a measurement technology that was simultaneously ultra-precise, reliable over the long term, and economically viable, ruling out standard solutions that were either too costly or complex.

Custom-Engineered Solution: An Osmosis Test Bench with Servo-Electric Volumetric Pumps

To meet this challenge, IRIAN MECATRONICS proposed an innovative solution based on two high-precision servo-electric volumetric pumps, positioned at the inlet and outlet of a custom-designed core holder cell.

The equipment’s architecture was engineered to ensure the highest measurement fidelity. Instead of using precision scales, which are expensive and sensitive to external disturbances, we opted for pumps whose technology ensures a direct and reliable measurement of the displaced volume.

- Unmatched Measurement Precision: The selected pumps, featuring a wheel and worm gear design, provide a volumetric resolution of 0.000001 cc and a pressure resolution of 0.001 bar. This configuration allows for the measurement of the minute volume variations required by the experiment while maintaining stable pressure even during a power failure.

- Optimized Core Holder Cell: A core holder cell was entirely designed in 316 stainless steel to house the sample. Diffusers were machined on the faces in contact with the rock to maximize the fluid exchange surface and ensure homogeneous distribution.

- Advanced Thermal Control: To create controlled temperature gradients, heating cartridges were integrated on both sides of the sample, managed by independent regulation loops. The hydraulic lines are also heat-traced to prevent any thermal fluctuations.

- Control and Data Acquisition: The entire bench is controlled by a Human-Machine Interface (HMI) developed in LabVIEW. It allows for test programming, real-time visualization of pressure, temperature, and injected volume, and the export of all data for analysis.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.