Fluid Dynamics & Phase Behavior / Test Benches & Experimental Pilot Units

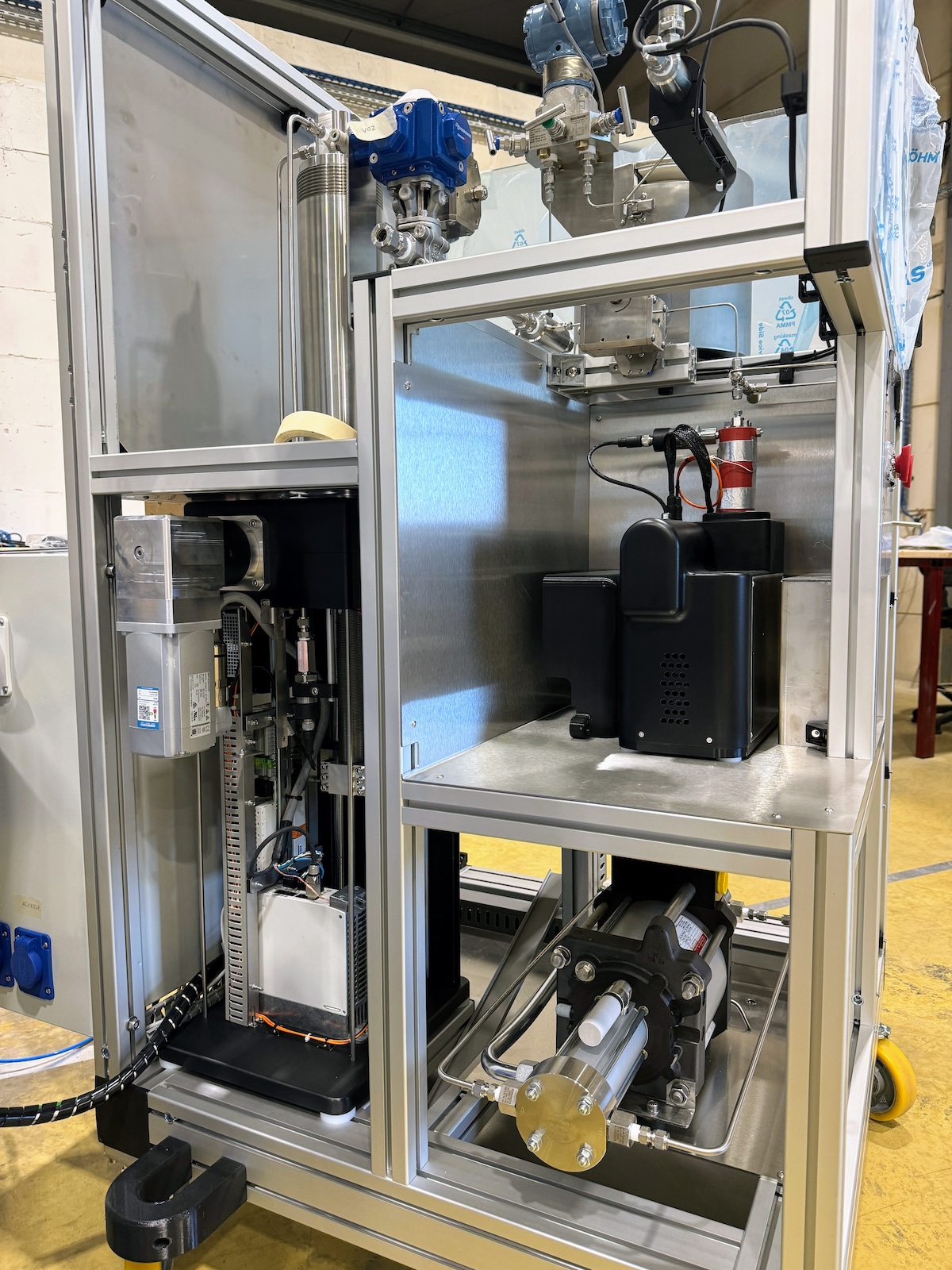

HPHT Pilot Unit for Simulating Turbulent Flow with DRA Agents

To optimize fluid transportation, a major player in the energy sector commissioned IRIAN MECATRONICS to design a custom pilot test unit. The objective was to develop a bench capable of simulating the turbulent flow of fluids (seawater, hydrocarbons) under pressure (50 bar) and temperature (70°C) conditions. Our solution allows for the precise measurement of pressure drop to evaluate the effectiveness of Drag-Reducing Agents (DRA).

The Challenge: Quantifying DRA Performance Without Shear Degradation

The client required an R&D tool to quantify the effect of DRA on pressure drop in pipelines. The pilot unit had to accurately replicate flow conditions and enable highly precise differential pressure measurements. The constraints were as follows:

- Turbulent Flow Simulation: The bench needed to achieve a Reynolds number between 5,000 and 50,000 for various fluids.

- HPHT Conditions: The system had to operate at up to 50 bar and 70°C.

- Experimental Flexibility: The pilot unit had to incorporate three interchangeable test columns of different diameters (1/8″, 1/4″, 1/2″) to vary flow conditions.

- Fluid Compatibility: The equipment needed to be compatible with a range of fluids, including seawater, hydrocarbons (gas and liquid), and high-salinity reservoir water.

- Minimized Shear Stress: The design had to strictly avoid shearing the DRA agents before they entered the measurement column to prevent skewed results.

Our Solution: A Low-Shear Pilot Unit for Precision DRA Testing

Our engineering department designed a complete pilot unit, paying special attention to fluid dynamics and instrumentation.

- Precision DRA Injection Pump: To inject the DRA agents without degradation, we designed and manufactured a specific low-shear syringe pump. The internal design, featuring the removal of sharp edges and an optimized outlet cone, ensures the integrity of the injected polymers—a critical condition for the validity of the measurements.

- Interchangeable Heated Columns: The core of the bench is a module that accommodates three 6-meter long columns, wound into coils. A clamshell-style heating system allows for uniform thermal regulation and quick column changes.

- High-Precision Instrumentation: To measure the pressure drop, a high-precision differential pressure sensor is installed as close as possible to the column inlets and outlets, minimizing tubing lengths and bends for an unbiased measurement.

- Low-Shear Circuit Design: The entire circuit was designed to preserve the fluids. Full-bore valves and straight-through fittings were used to eliminate diameter restrictions and abrupt changes in direction.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.