Extreme Environment Simulation Systems / Fluid Dynamics & Phase Behavior / Geoscience & Subsurface Studies / Test Benches & Experimental Pilot Units

Design and Delivery of a Turnkey PVT Laboratory for ENSP (Sonatrach) with Custom High-Pressure Equipment

The Algerian National Company for Well Services (ENSP), a subsidiary of the Sonatrach group, commissioned IRIAN MECATRONICS to design, supply, and install a turnkey PVT laboratory.

This major project involved delivering a complete and integrated solution, with a significant portion of the high-pressure equipment designed and manufactured by our in-house engineering department to meet the most stringent performance and safety standards.

The Challenge: Delivering a Complete Solution for Fluid Characterization under Extreme Conditions

To optimize its field development and production, ENSP required a comprehensive laboratory to characterize its reservoir fluids with maximum reliability. The project specifications called for a global, high-performance, and fully integrated solution.

The main constraints were as follows:

Turnkey Laboratory Solution: The requirement was for a complete solution, from sample preparation to compositional analysis by gas chromatography, including installation, training, and long-term technical support.

Extreme Testing Conditions: The equipment had to operate reliably at pressures up to 1000 bar (14,500 psi) and temperatures up to 200°C (392°F) to simulate actual reservoir conditions.

High Measurement Accuracy: Absolute precision was required for volume, pressure, temperature, and viscosity measurements.

Safety and Environmental Compliance: A non-negotiable requirement was the design of completely mercury-free systems.

IRIAN MECATRONICS’ Expertise: At the Core of High-Pressure Design

Faced with this demanding set of specifications, our engineering team developed a complete laboratory solution, combining equipment from renowned partners with a full range of high-pressure systems entirely designed and manufactured in-house. Our engineering expertise was the cornerstone of this project.

Our Custom-Engineered Systems at the Heart of the Laboratory:

Our contribution was not limited to integration; we mastered the design and fabrication of the entire high-pressure analysis chain:

Heating Trolley and Recombination Cell: For the safe preparation and conditioning of samples before analysis.

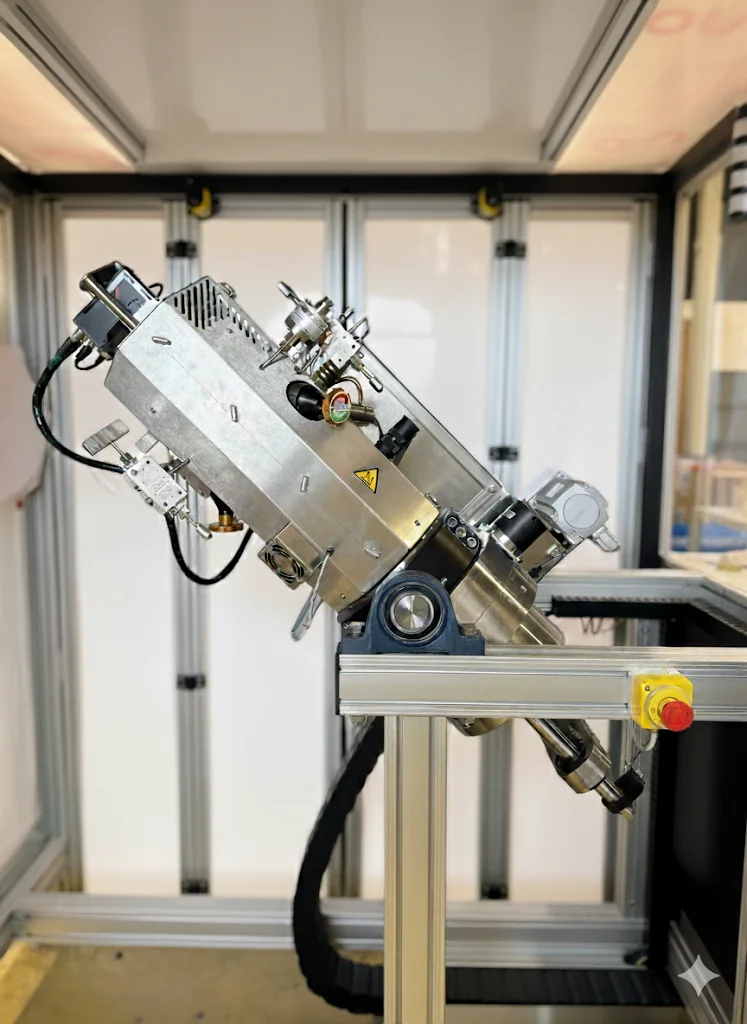

HP-HT PVT Cell (400 cc): The centerpiece of the laboratory, optimized for precision with its electrical cartridge heating system, rocking system for agitation, and HD camera for phase detection.

High-Pressure Pump and Gasometer: Essential systems for precise pressure control and gas volume measurement.

Flash GOR Apparatus: A custom-built unit to determine the gas-oil ratio under controlled separation conditions.

HP-HT Capillary Viscometer: To complement the studies, this device measures fluid viscosity at up to 1000 bar, 200°C, and 6000 cP.

HP Pycnometers: For the accurate density measurement of both liquid and gas samples under pressure.

By delivering a complete laboratory solution and mastering the manufacturing of its most critical components, IRIAN MECATRONICS not only met ENSP’s technical specifications but also solidified its position as an integrator and manufacturer of complex solutions for the Oil & Gas industry.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.