Custom HPHT Reactors, Autoclaves & Analysis Cells

Our core expertise is the design and fabrication of custom HPHT pressure vessels, including reactors, autoclaves, and analysis cells.

We engineer reactors for research and industry, designed for chemical reactions (catalysis, polymerization, corrosion) and often equipped with magnetic drive agitation or specialized heating systems.

In parallel, we develop complex analysis cells for physical testing and metrology. These integrate advanced designs (floating pistons, sapphire windows, X-ray transparency) for applications such as PVT analysis, geomechanics, or flow assurance.

Engineering for Experimental Research

The implementation of high-pressure, high-temperature (HPHT) experiments requires equipment specifically designed to meet the constraints of the process. Whether dealing with multiphase systems (gas-liquid-solid) or chemically corrosive environments, we design each reactor as a scientific instrument, where every component is selected for its performance and reliability.

Our approach is based on a detailed analysis of your specifications to deliver a robust, fully validated, and “plug and play” technical solution.

Custom Performance. Standard Cost.

Custom equipment doesn’t mean starting from a blank slate for every project. Our design approach is based on integrating proven “design blocks” for essential functions (e.g., agitation systems, sealing, and regulation).

Our engineers combine these reliable, standardized modules with elements designed specifically for your needs to create high-performance equipment that is optimized in terms of cost and lead time. This gives you a solution perfectly adapted to your process, with the robustness of field-tested components and a controlled budget comparable to a standard solution.

Operating Parameters and Vessel Design

Operating Range: The volume, working pressure, and temperature are defined to match your specific testing conditions.

Wetted Materials: We select materials (316 Stainless Steel, Nickel alloys, Titanium, etc.) and seal elastomers (FFKM, etc.) based on chemical compatibility with your reactants and the thermal conditions.

Ports and Connections: The reactor head is configured with the necessary number of ports for instrumentation, fluid injection, sampling, and safety devices.

Advanced Functionality & Integrated Design

A pressure vessel is more than a container; it’s a tool. We integrate the specific functionalities your protocol requires, whether for chemical reaction or physical analysis.

Common features include:

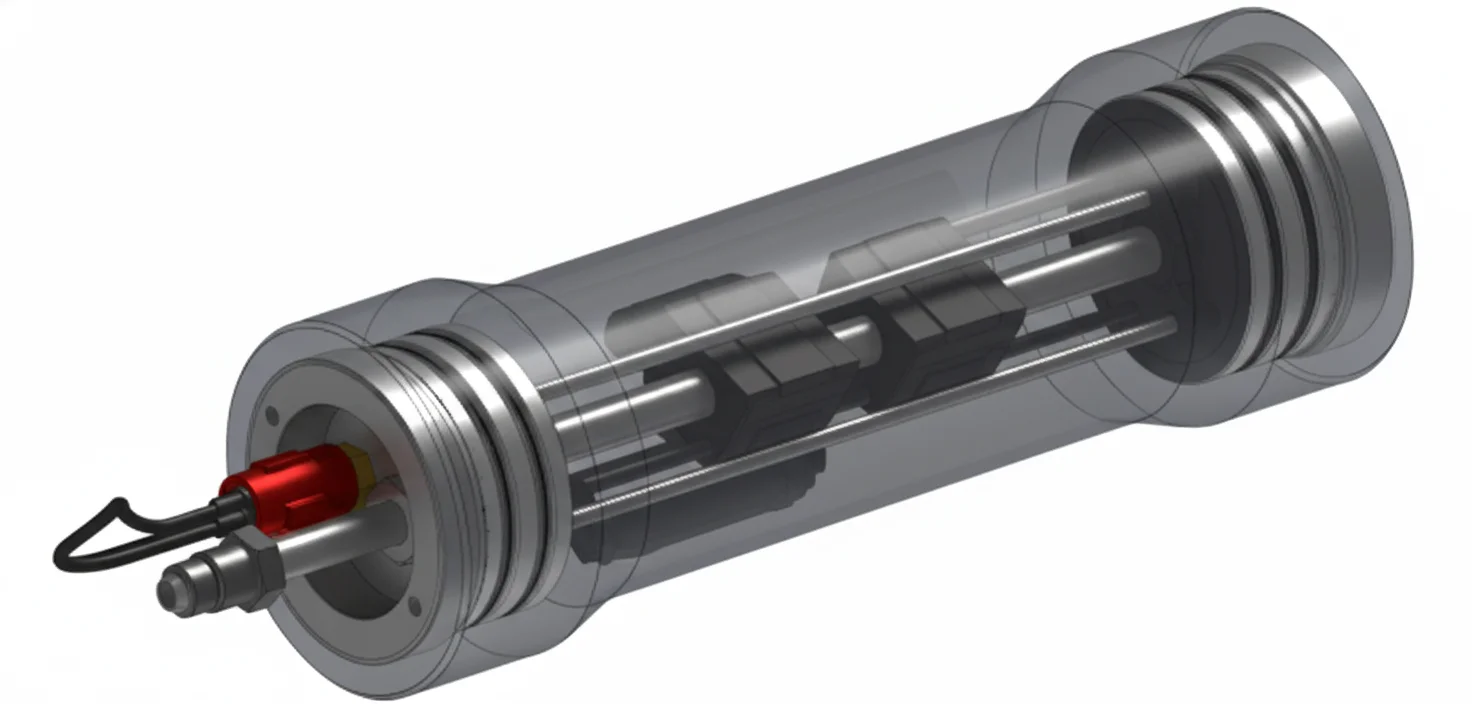

Agitation Systems: Hermetically sealed magnetic drives for reactors, ensuring controlled hydrodynamics (e.g., gas-inducing turbines, anchor stirrers).

Visualization & Optical Access: Sapphire viewports for direct observation or in-situ spectroscopy.

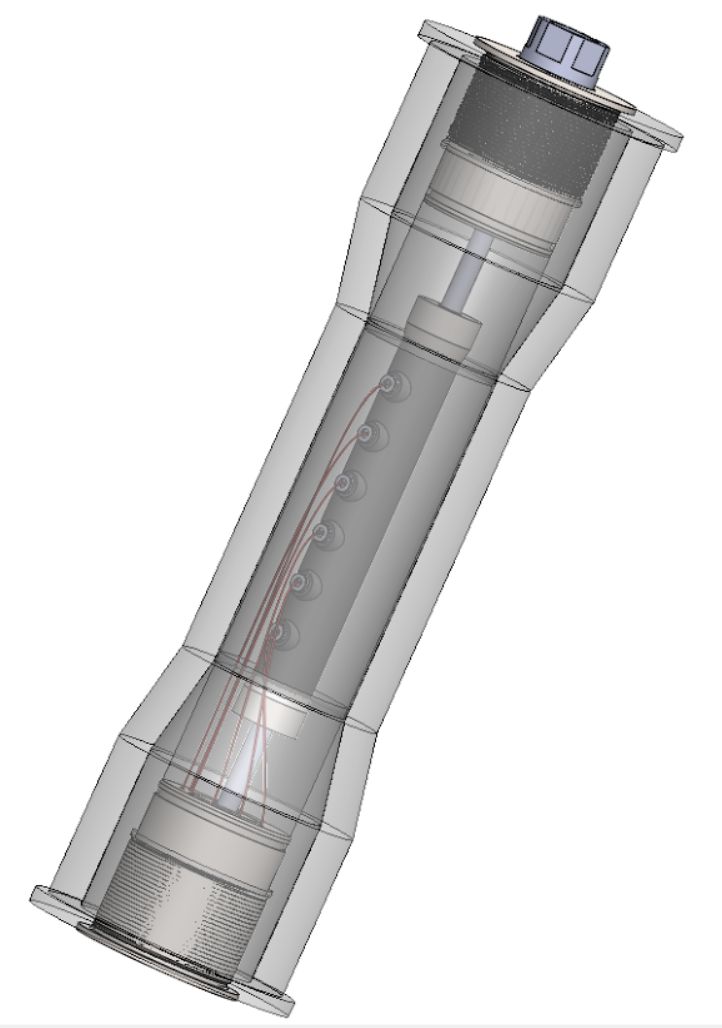

Specialized Metrology: X-ray or neutron-transparent designs (using PEEK or Titanium) for in-situ tomography (geomechanics).

Volume Control: Floating or motor-driven pistons for applications like PVT analysis or fluid displacement.

Heating & Cooling: Custom heating jackets, double-wall designs, or internal/external cooling loops.

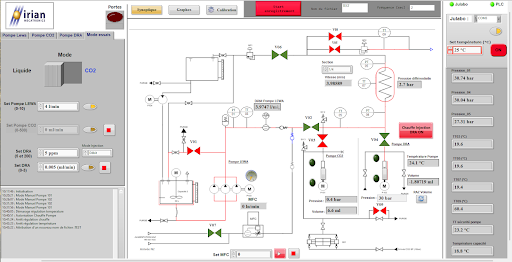

Control and Data Acquisition

Full System Control: Our control system, built around a Programmable Logic Controller (PLC) and a Human-Machine Interface (HMI) on a PC, is developed entirely by our own control systems engineers. This guarantees deep customization and direct, expert support.

Fine-Tuned Process Management: The user interface enables the configuration of precise setpoints and programmed ramps for parameters like agitation speed, temperature, and pressure.

Comprehensive Data Logging: All sensor readings, including pressure, temperature, and torque, are recorded, displayed live on-screen, and can be easily exported for detailed analysis.

Aeras of Application

Our custom reactors and cells are used across diverse research and industrial fields:

Chemical & Process R&D: Catalysis, polymerization, synthesis, biomass valorization.

Materials Science: Corrosion testing, material aging, hydrogen embrittlement.

Geoscience & Subsurface: PVT analysis, geomechanics, fluid-rock interaction, core flooding.

Physics & Metrology: Phase behavior studies, flow assurance, in-situ analysis (X-ray).

FAQ

Reactor & Cell Project Examples

Wide-Range Gas Permeability Test Bench and Triaxial Cell for Geomechanics

Wide-range gas permeability bench ($10^{-21} m^2$) with triaxial cell for the University of Shandong. An IRIAN MECATRONICS solution for tight rock characterization.

500 bar / 150°C Titanium Variable Volume Cell for HP Fluid Research

50 mL / 500 bar Titanium variable volume cell. Features magnetic stirring, safety worm gear drive, and double-flange sapphire.

Marinized 6000m Flowmeter: Qualifying Measurement in Extreme Environments for Oceanographic Research

6000m flowmeter for marine research. A HP housing protects a non-intrusive sensor for reliable deep-sea measurement.

High-Pressure Reactor 550 bar for Geoscience Research

For the BRGM, we designed an HP reactor (550 bar, 250°C) made of Alloy 625. It resists the most corrosive fluids, including H₂S, for rock sample studies.

1200‑bar Floating Piston Cells for HPHT Reservoir Fluid Studies

We built 1200 bar HPHT floating piston cells (up to 5L) for reservoir fluid studies. Made of Super Duplex F53, they resist corrosive fluids (brines, CO2).

500°C / 130 bar Corrosion Test Reactors for Materials Research

For IFPEN, we designed two reactors (500°C, 130 bar) for corrosion testing. The Inconel 625 solution withstands oxidizing gases at very high temperatures.

Custom X-ray Transparent Triaxial Cell for BRGM: In-Situ 3D Tomography Analysis

For the BRGM, we designed an X-ray transparent triaxial cell (200 bar, 150°C). Made of PEEK and titanium, it allows for in-situ 3D analysis of rocks under stress.

Do your operating conditions require a specific design?

Complex fluids, extreme temperatures, or high pressure: our engineering team designs the vessel (Reactor or Cell) adapted to your specifications.