Fluid Dynamics & Phase Behavior / Test Benches & Experimental Pilot Units

1000 Bar High-Pressure Injection Bench for Extreme Low-Temperature (-70°C) Microfluidic Studies

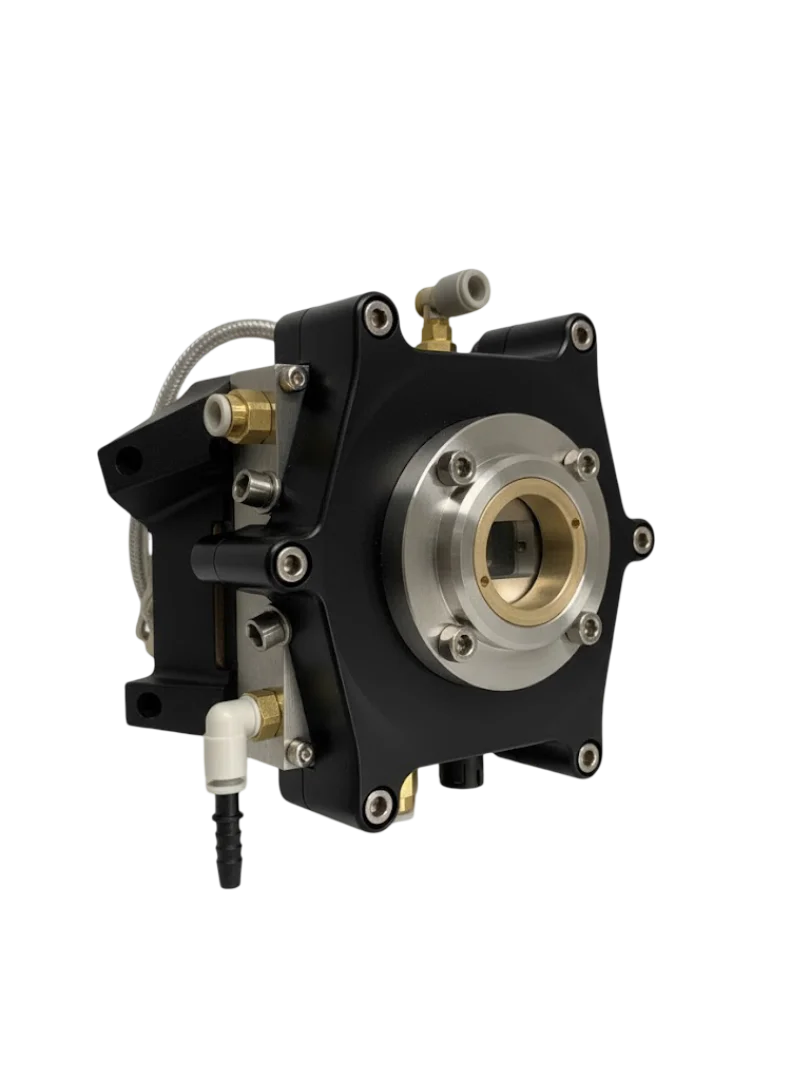

For a leading research institution specialized in fluid characterization, IRIAN MECATRONICS engineered a bespoke test bench. The core challenge was to inject fluid at extreme high pressure (1000 bar) into a microfluidic network maintained at a cryogenic temperature of -70°C. Our solution delivered a compact, modular system providing ultra-precise control over both pressure and temperature, alongside pristine visualization of the experimental process.

The client required an equipment capable of simulating extreme conditions to investigate fluid behavior at the micro-scale, a critical need for applications ranging from materials science to biochemistry under non-standard conditions. The technical specifications presented significant engineering challenges, demanding a compact and highly reliable system.

Key technical requirements included:

Extreme High Pressure: Achieving and consistently maintaining an injection pressure up to 1000 bar, simulating deep environments or intense industrial processes.

Extreme Low Temperature: Ensuring precise thermal regulation within the microfluidic network down to -70°C, essential for studying cryogenic fluids or low-temperature reactions.

Integration & Visualization: Seamlessly integrating a specific microfluidic network ( mm) and enabling clear, unobstructed observation of the experiment via a viewing window, free from frosting or condensation.

Specific Connectivity: The system needed 4 high-pressure 1/16″ VALCO connection ports to allow for experimental flexibility.

Controlled Environment: An inerting chamber was essential to protect the microfluidic network from ambient humidity and ensure measurement stability, particularly critical at very low temperatures.

Measurement Accuracy: Temperature monitoring had to be performed by high-precision PT1000 sensors, one in direct contact with the microfluidic network, for reliable thermal characterization.

Responding to these stringent requirements, our engineering office developed a comprehensive, integrated mechatronic solution, featuring two compact and interconnected modules.

The injection module forms the heart of the system. To ensure both 1000 bar pressure resistance and compatibility with diverse injection fluids, all wetted parts were meticulously machined from stainless steel. Managing the cryogenic temperature was a primary design hurdle. We opted for a miniature oven with a dual Peltier effect, a thermoelectric cooling technology enabling precise, vibration-free, and highly responsive temperature control down to -70°C. The cold face of the Peltier element is in direct contact with the microfluidic network’s support component, maximizing thermal exchange and regulatory precision.

To prevent condensation and frosting on the viewing window during cooling, we engineered a sealed inerting chamber (max. 0.2 bar pressure). The selection of a Quartz viewing window was strategic: this material offers exceptional optical transparency for observation or instrumentation, while also acting as an excellent thermal insulator, minimizing heat loss and protecting the integrity of the experiment and measurements.

The second cooling module acts as an active heat sink. It comprises a second Peltier element and an insulated heat exchanger, where a pump circulates water to efficiently dissipate heat extracted from the injection module. This system ensures sustained performance, stability, and longevity, even during prolonged experiments at extreme low temperatures.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.