Extreme Environment Simulation Systems / Geoscience & Subsurface Studies / Test Benches & Experimental Pilot Units

Multi-Cell 400 bar / 250°C Test Bench for Formation Damage Analysis

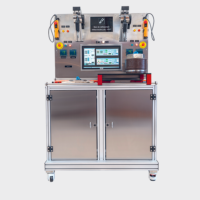

As part of a strategic R&D partnership with a global energy leader, IRIAN MECATRONICS designed and manufactured a custom test bench to simulate extreme drilling conditions. The challenge was to quantify, with high precision, the damage to reservoir rock from contact with complex drilling fluids. The result is a unique multi-cell system, operating at high pressure and high temperature (HPHT) and capable of withstanding particularly aggressive chemical environments.

Meeting the Challenges of High-Pressure, High-Temperature Drilling Simulation

Faced with this technical challenge, our engineering department developed a proprietary solution combining robustness, precision, and safety. The bench’s architecture was entirely designed to meet the extreme constraints of corrosion and high pressure.

- Strategic Material Selection: To ensure total resistance to highly corrosive fluids, particularly HCl acid, we specified the use of Hastelloy® for all wetted parts (cell bodies, tubing, valves). This high-performance alloy ensures the equipment’s longevity and the purity of the tests.

- HPHT Cells with Floating Piston: Each cell was designed to withstand 400 bar and is equipped with a regulated heating system using collar heaters. An internal floating piston automatically adjusts to the sample’s height, providing great flexibility for testing different rock sizes.

- Modular and Ergonomic Frame: The robust frame is designed to hold the three cells vertically. To facilitate the handling of the heavy cell plugs, a sliding rail system and an electric hoist were integrated, ensuring safe and efficient maintenance and sample loading operations.

- Integrated Injection and Circulation System: The bench includes Hastelloy® fluid transfer cells, a dedicated circulation loop for muds, and a control panel for gas injection. Each circuit is instrumented with high-precision pressure sensors for detailed monitoring of test parameters.

- Centralized Control and Data Acquisition: The entire system is controlled by custom software that allows for programming injection sequences, regulating temperature and pressure, and recording all data in real-time to an exportable file, ensuring complete traceability and easy analysis of the results.

Modular Hastelloy Bench Design for Reliable HPHT Testing

In response to these specifications, our design office developed a technical solution based on the following choices:

Material Selection: Inconel 625 was chosen for all wetted parts (reactor body, lid, agitator) due to its compatibility with corrosive environments at 500°C. A286 Stainless Steel was used for the bolts for its high-temperature mechanical properties.

Sealing System: As the service temperature makes elastomers and thermoplastics unusable, the seal is provided by a metallic axial gasket. This type of seal is designed for single use to ensure performance with each closure.

Agitation System: A magnetically coupled agitator was integrated. This technology eliminates the need for a rotating shaft pass-through, a potential source of leaks under HPHT conditions. The design keeps the motor away from the hot zone to preserve its durability.

Safety Devices: The equipment’s safety is ensured by redundant devices. Overpressure is managed by a rupture disc (mechanical safety) and a heater cut-off linked to the pressure sensor (passive safety). Overheating is prevented by a passive safety feature from a second thermocouple that cuts power to the heating collar.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.