Extreme Environment Simulation Systems / Process Development & Chemical Pilot Plants / Test Benches & Experimental Pilot Units

High-Pressure Autoclaves for Flammable Gas (ATEX) Testing

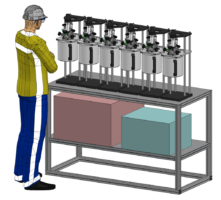

IRIAN MECATRONICS has recognized expertise in designing high-pressure test benches intended for use with hazardous or flammable gases, such as hydrogen. On behalf of an R&D center, we developed the complete engineering for a dual autoclave bench, designed to perform material aging tests in a high-pressure, high-temperature reactive gas environment. Our design focused on comprehensive ATEX risk management and operational ergonomics.

Ensuring Absolute Safety in HP/HT Flammable Gas Tests

The primary challenge for any equipment of this type is managing the risk associated with the process fluid, whether it is hydrogen or another flammable gas. These gases have low flammability thresholds and impose drastic design constraints to ensure the safety of operators and the facility.

Key requirements included:

ATEX Safety: The bench had to be designed for use in a potentially explosive atmosphere, involving a complete safety strategy to prevent any ignition risk in case of a leak.

Material Compatibility: The need to select specific materials for the autoclaves to prevent degradation phenomena (such as hydrogen embrittlement).

Independent Control: The ability to operate multiple autoclaves with fully independent pressure and temperature control.

Process Performance: Ensuring rapid temperature and pressure ramp-up, as well as efficient gas neutralization (via vacuum and purge) before any opening.

Ergonomics: Simplifying the handling of the autoclave lids for sample loading and unloading.

A Design Focused on ATEX Safety and Operational Ergonomics

Facing the risks of flammable gases, our engineering team designs systems where safety and ease of use are at the core of the engineering.

Multi-Level ATEX Safety Explosion risk management is the pillar of our design. Our approach combines three levels of protection:

ATEX-Certified Components: All electrical equipment in the process area (heating systems, pumps, sensors) is certified for use in explosive atmospheres.

Zoning and Containment: The PLC and control cabinet are located remotely in a “safe area,” separated from the test area by a sealed and certified wall pass-through.

Active Detection and Purge: Gas detectors (e.g., hydrogen) monitor the test area. Upon detection, the system automatically triggers a safety shutdown sequence, including process stop and a full nitrogen purge of the cells.

Anti-Embrittlement Materials and Treatments To ensure the longevity of autoclaves against gases like hydrogen, we do not use standard 316L stainless steel. Our engineers select specific high-nickel grades and can supplement them with surface treatments (like nitriding). This dual technical choice ensures the material’s long-term integrity and reduces the risk of thread galling.

Ergonomic Maintenance (Design for Maintenance) To simplify loading operations, the bench integrates a manual lifting system (hoist) to assist the operator. Furthermore, the autoclave lids are connected to the pressure circuit via high-pressure flexible hoses. The benefit is twofold: the operator does not have to bear the lid’s weight and, critically, does not need to disconnect the rigid HP tubing to open it, saving time and increasing safety.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.