Water Meter Test Bench: Automated Dual Syringe Pump for Wide Flow Ranges

For Sagemcom, a leader in smart metering solutions, the challenge was to validate fiscal water meters over an extremely wide operating range while strictly controlling fluid temperature. IRIAN MECATRONICS designed a custom solution based on a dual syringe pump architecture, ensuring metrological precision from very low to high flow rates.

Hydraulic Metrology Challenges: Flow Amplitude and Thermal Stability

The requirements analysis highlighted a major constraint: the need to cover a considerable flow dynamic range with a single piece of equipment, whilst maintaining strict test conditions.

Critical Flow Gap: The bench had to manage continuous injection ranging from 1 L/h (very low flow) up to 5500 L/h (high flow)—a ratio that makes using a single pump ineffective for maintaining required precision across the entire range.

Mastering Thermal Inertia: Tests must be performed at constant temperatures (+25°C or +50°C). However, the metallic mass of pump barrels naturally generates thermal inertia, delaying stabilization and potentially skewing volumetric measurements during setpoint changes.

Precision Under Pressure: The equipment must operate up to 16 bar. At these pressures, mechanical deformation of materials, however minimal, can impact the accuracy of the injected volume if not compensated.

Hybrid Architecture and Active Compensation: Targeted Engineering

Instead of using multiple setups, our engineering department opted for the intelligent integration of complementary technologies within a single chassis:

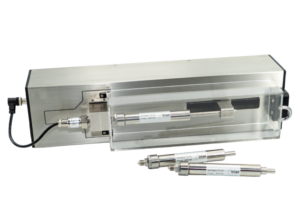

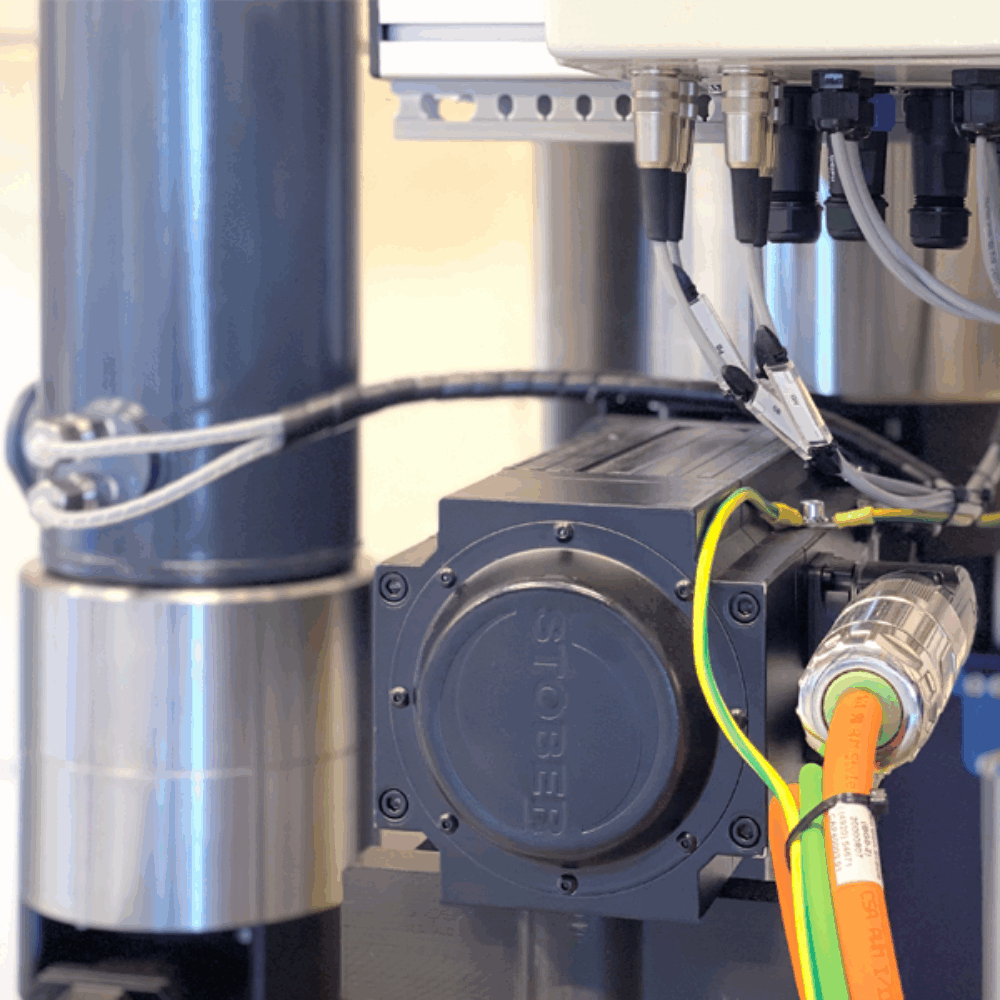

Hybrid Motorization for Absolute Precision: To guarantee perfect linearity and repeatability across the entire test spectrum (1 L/h to 5500 L/h)—without compromising between drip-feed precision and full-flow power—we implemented a “Dual Pump” architecture driven by specialized motors: stepper technology for fine low-flow resolution and brushless synchronous motors for high-torque high-flow requirements.

Double-Jacketed Barrels for Thermal Reactivity: To drastically reduce temperature ramp-up times—achieving a 50°C to 25°C transition in under 10 minutes—and increase operational availability, we designed barrels equipped with insulated double outer jackets for active fluid circulation, ensuring the injected fluid temperature strictly adheres to normative setpoints.

Deformation Correction Algorithms: We ensure the accuracy of the delivered volume regardless of service pressure (up to 25 bar) by integrating specific correction charts directly into the control logic, essentially transforming the unavoidable mechanical expansion of the barrels into a controlled, transparent parameter for the user.

Does your application impose specific injection constraints?

Complex fluids, high pressure, or process integration: our engineering team sizes the system adapted to your experimental protocol.