500 bar / 150°C Titanium Variable Volume Cell for HP Fluid Research

50 mL / 500 bar Titanium variable volume cell. Features magnetic stirring, safety worm gear drive, and double-flange sapphire.

As a specialist in high-pressure fluid management, IRIAN MECATRONICS presents on this page an overview of our expertise in precision pumps and injection systems. Each piece of equipment is a robust solution, designed to deliver fluids with extreme accuracy and repeatability, whether for pressure control, precise dosing, or feeding reactors.

Our expertise covers a wide range of technologies and applications:

HPHT Volumetric Pumps: Designs reaching up to several thousand bar, ensuring stable flow and pressure control for applications such as geoscience or materials research.

Precision Dosing Systems: Syringe pumps allowing for very low and stable flow rates (µL/min) for applications in fine chemistry, microfluidics, or laboratory settings.

Custom Solutions: Adaptation of materials (stainless steel, Hastelloy®), volumes, and control systems for perfect compatibility with complex fluids (corrosive, viscous, supercritical).

50 mL / 500 bar Titanium variable volume cell. Features magnetic stirring, safety worm gear drive, and double-flange sapphire.

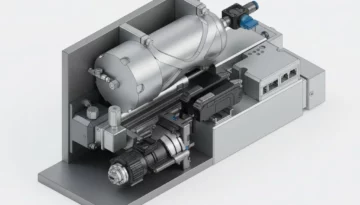

300 bar pump & regulation modules for SCWO experiment in microgravity (ISS). Manages reactive fluids (H2O2) & microflows (µL/min).

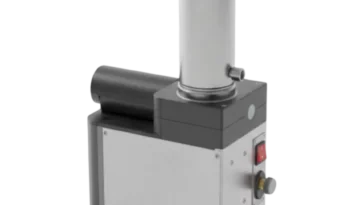

2L / 15 bar volumetric pump for 98% sulfuric acid (H₂SO₄) injection. Expertise in Super Duplex and FKM materials.

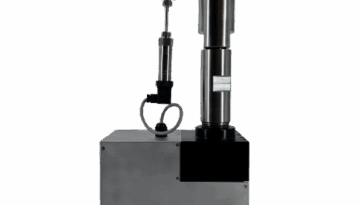

For a major energy client, we designed this 750-bar positive displacement pump. It provides precise confinement management for reservoir fluid experiments.

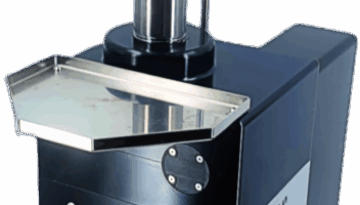

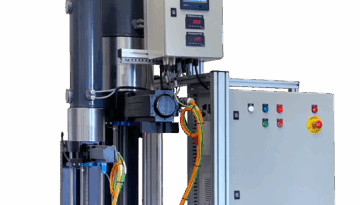

Replaced a manual pump with an automated 6000 bar / 6 mL pump for GEPEA (ONIRIS/CNRS). Features PC control and a non-reversible drive.

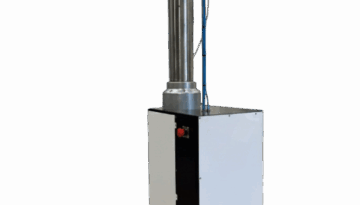

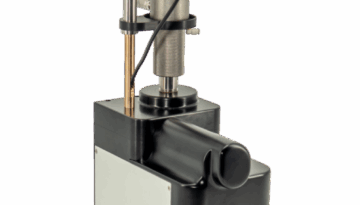

For the CNRS (Bacterial Chemistry Lab), we designed this 600 bar pump. It provides precise pressure regulation for a 500 µL observation cell.

We carried out a complete refurbishment of two HP positive displacement pumps. The project included mechanical overhaul and modernization of the automation and user interface.

For a manufacturing leader, we designed a dual volumetric pump (200 bar) for the precision mixing of reactive fluids (polymer, abrasive suspensions).

For the ICMCB (CNRS), we designed these 800 bar syringe pumps in Hastelloy. They simulate hydrothermal vents by injecting corrosive fluids with extreme stability.

Dual syringe pump test bench for Sagemcom. Flow range from 1 to 5500 L/h, active thermal regulation, and high metrological precision.