Extreme Environment Simulation Systems / Test Benches & Experimental Pilot Units

1000 bar High-Pressure Test Bench with Dual Titanium Cells for Deep-Sea Environment Simulation

For CEREGE, a CNRS geoscience research laboratory, IRIAN MECATRONICS designed and manufactured two identical, custom-made test benches. These systems simulate the extreme conditions of the seabed (1000 bar, 2°C) to study seawater samples and the microorganisms they contain in their native environment.

Objective: A 1000 Bar Deep-Sea Simulation Bench

CEREGE needed to reproduce the pressure and temperature conditions of deep-sea ecosystems in a laboratory setting to conduct cutting-edge research. The specifications presented major technical challenges, requiring a solution that combined high pressure, low temperature, biocompatibility, and advanced instrumentation capabilities.

The main constraints were as follows:

- Very High Pressure: To reach and maintain a stable pressure of up to 1000 bar, equivalent to a depth of 10,000 meters.

- Low Temperature: To ensure precise thermal regulation within a range of 2°C to 30°C to simulate actual deep-sea conditions.

- Material Compatibility: To use materials perfectly resistant to seawater corrosion and fully biocompatible to avoid contaminating biological samples, specifically Titanium (Ti-6Al-4V).

- Multiple Experiment Configurations: To design a dual system, with a primary cell for testing multiple samples simultaneously (in vacutainers) and a second, larger volume cell (2L) for global analyses.

- Measurement Integrity: To allow the integration of specific optical sensors (O2, pH) through multiple high-pressure, sealed fiber optic feedthroughs.

- Sampling without Depressurization: To develop a method for collecting fluid samples under 1000 bar of pressure without altering their biological integrity due to a pressure drop.

Custom-Designed System with Dual Titanium Cells

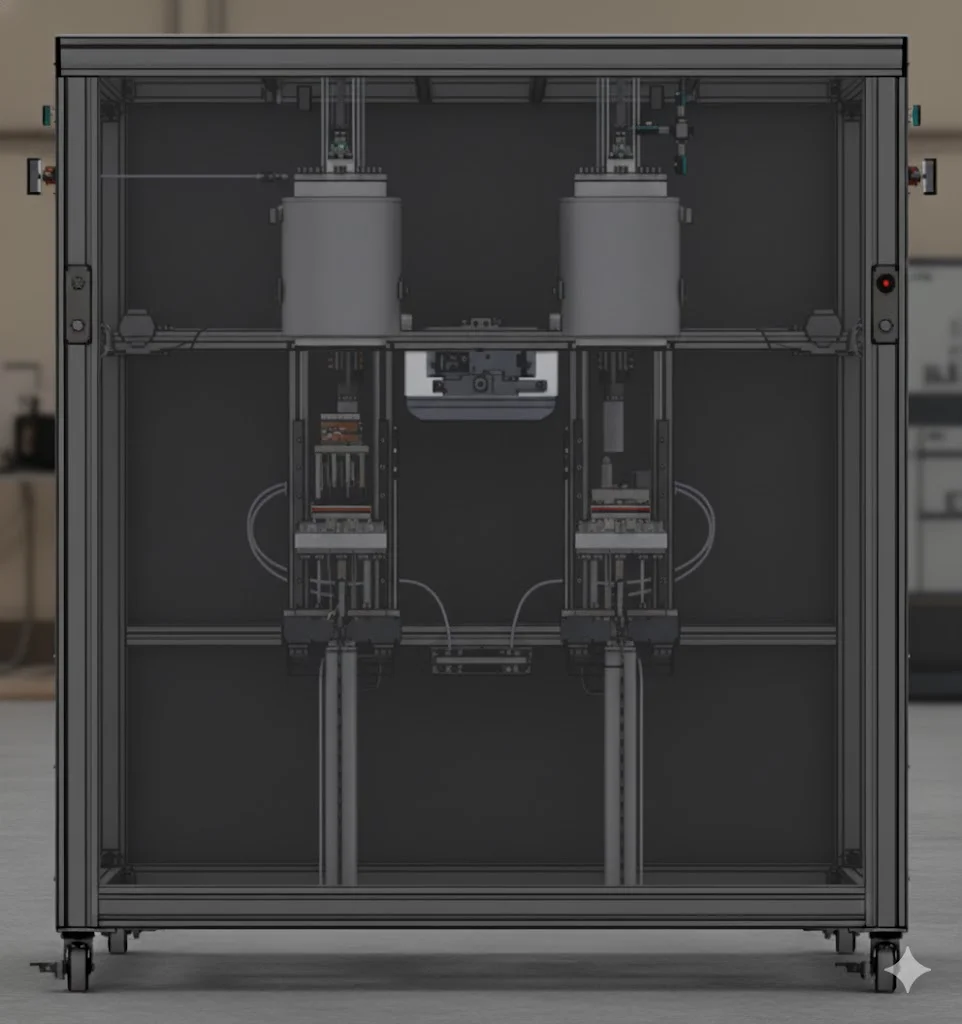

Faced with these demanding specifications, our design office developed a complete and integrated solution. Each bench is built around two distinct high-pressure cells, mounted on a single mobile chassis that incorporates all functionalities.

Custom-Made Titanium Cells: The core of the system is based on two reactors machined from Ti-6Al-4V titanium. This strategic choice guarantees exceptional resistance to saline corrosion and perfect biocompatibility, essential for CEREGE’s experiments. Each cell is equipped with a double jacket for the circulation of a heat-transfer fluid, ensuring ultra-precise thermal regulation controlled by a high-performance thermostatic bath.

Dual Independent Pressurization System: To offer maximum flexibility and prevent any cross-contamination, we integrated two separate pumps.

A custom-built syringe pump is dedicated to the vacutainer cell. It provides extremely precise volumetric control, which is essential for pressurization and compensating for thermal variations.

A dual-piston volumetric pump supplies the 2L cell. Its technology ensures a continuous, pulse-free flow and allows it to instantly compensate for the volume withdrawn during sampling, maintaining the set pressure without interruption.

Innovative Agitation and Sampling System: For the vacutainer cell, an individual magnetic drive system was designed to stir each sample independently and under control. For the 2L cell, an isobaric sampling system was specifically developed. It consists of a titanium syringe operated by a pneumatic actuator, allowing a sample to be collected at 1000 bar and transported sealed to analysis instruments, thereby completely preserving the integrity of the microorganisms.

The entire system is controlled by a human-machine interface (HMI) offering full control over parameters (pressure, temperature, agitation), real-time data acquisition, and safety management.

FAQ

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.