500°C / 130 bar Corrosion Test Reactors for Materials Research

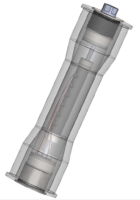

On behalf of IFP Energies Nouvelles (IFPEN), IRIAN MECATRONICS designed and manufactured a dual high-pressure, high-temperature (HPHT) reactor system. This equipment is intended for corrosion studies on materials under service conditions of 130 bar and 500°C.

The Challenge: A 500°C HPHT Reactor with Flexible Agitation

The project’s scope of work specified the following technical constraints for conducting the tests:

- Material Resistance: Use of a specific corrosion-resistant alloy for the construction of the two reactors.

- Operating Conditions: Service pressure of 130 bar and a maximum temperature of 500°C.

- Internal Volume: Required capacity between 0.6 and 0.75 L per reactor.

- Agitation System: The device had to be compatible with both a propeller and a rotating cage.

- Independent Control: Each reactor required its own heating system.

- Connectivity: The lid of each reactor had to feature a minimum of three ports for instrumentation and fluids.

Our Solution: A 500°C Inconel 625 Reactor with Magnetic Coupling

In response to these specifications, our design office developed a technical solution based on the following choices:

- Material Selection: Inconel 625 was chosen for all wetted parts (reactor body, lid, agitator) due to its compatibility with corrosive environments at 500°C. A286 Stainless Steel was used for the bolts for its high-temperature mechanical properties.

- Sealing System: As the service temperature makes elastomers and thermoplastics unusable, the seal is provided by a metallic axial gasket. This type of seal is designed for single use to ensure performance with each closure.

- Agitation System: A magnetically coupled agitator was integrated. This technology eliminates the need for a rotating shaft pass-through, a potential source of leaks under HPHT conditions. The design keeps the motor away from the hot zone to preserve its durability.

- Safety Devices: The equipment’s safety is ensured by redundant devices. Overpressure is managed by a rupture disc (mechanical safety) and a heater cut-off linked to the pressure sensor (passive safety). Overheating is prevented by a passive safety feature from a second thermocouple that cuts power to the heating collar.

Do your operating conditions require a specific design?

Complex fluids, extreme temperatures, or high pressure: our engineering team designs the vessel (Reactor or Cell) adapted to your specifications.