1200‑bar Floating Piston Cells for HPHT Reservoir Fluid Studies

To support advanced studies on petroleum reservoir fluids, a major energy industry player commissioned IRIAN MECATRONICS to design and manufacture six floating piston cells. The project aimed to deliver robust storage and transfer equipment capable of replicating the high-pressure, high-temperature (HPHT) conditions of reservoirs while ensuring full compatibility with complex and corrosive fluids.

The Challenge: 1200 bar Cells Combining Large Volume and Fluid Versatility

The laboratory required a versatile set of storage cells to handle samples under conditions representative of oil fields. The technical challenges were both numerous and demanding:

- Extreme conditions: The cells had to operate reliably up to 1200 bar and 150°C.

- Fluid compatibility: Materials had to withstand a wide range of fluids, including water, brines, liquid and gaseous hydrocarbons, and CO₂-containing mixtures.

- Volume flexibility: Large-volume cells ranging from 2 to 5 liters were required to accommodate substantial sample preparation.

- Ergonomics and safety: Equipment needed to be easy to handle in the laboratory, including for rotation (to mix fluids) and disassembly, while incorporating redundant safety features.

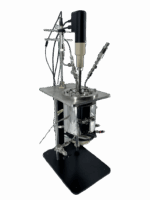

Our Solution: Super Duplex F53 Cells on a Secure Rotating Frame

Building on proven and certified designs, our engineering team proposed a solution available in two formats to meet all requirements. Metallurgical expertise was central to the project.

To ensure exceptional mechanical strength and chemical inertness against brines and CO₂, all fluid-contact components were machined from Super Duplex Stainless Steel F53 (1.4410). This material choice guarantees equipment longevity and prevents sample contamination, even after numerous HPHT cycles.

Ergonomics were enhanced with a custom mobile frame equipped with lockable casters and a bearing-mounted clamping system. This support allows each cell to be manually rotated for fluid homogenization and securely locked in place via an indexing pin. Thermal regulation is provided by heating collars, protected by an insulated cover to ensure operator safety.

Do your operating conditions require a specific design?

Complex fluids, extreme temperatures, or high pressure: our engineering team designs the vessel (Reactor or Cell) adapted to your specifications.