Extreme Environment Simulation Systems / Fluid Dynamics & Phase Behavior / Test Benches & Experimental Pilot Units

Custom 120 bar Sapphire Column for Gas Hydrate Research

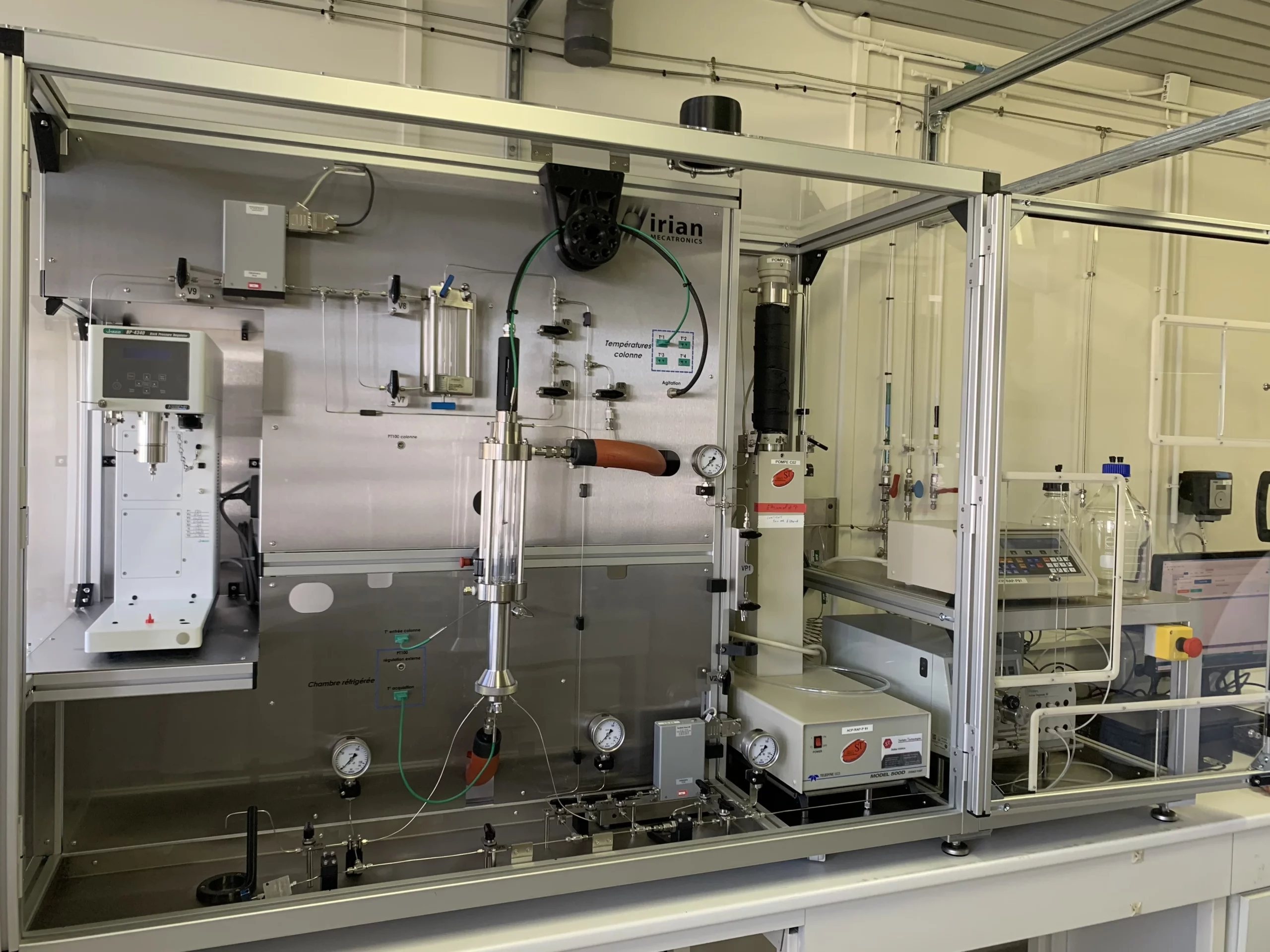

A global energy leader commissioned IRIAN MECATRONICS to design and manufacture a custom high-pressure test bench for its R&D center. The objective was to precisely study the formation of gas hydrates under controlled pressure and temperature conditions. Our engineering team developed a unique and versatile solution: a 120-bar sapphire tube column, built from titanium, and featuring two interchangeable experimental setups to simulate different reservoir conditions.

The Challenge: Visualizing and Quantifying Hydrate Formation in a Corrosive Environment

To advance its research on gas hydrate management, a key challenge in hydrocarbon transportation, our client required laboratory equipment capable of replicating complex phenomena while allowing for direct observation. The specifications were particularly demanding, combining constraints of visualization, materials, versatility, and metrology.

The key technical requirements were as follows:

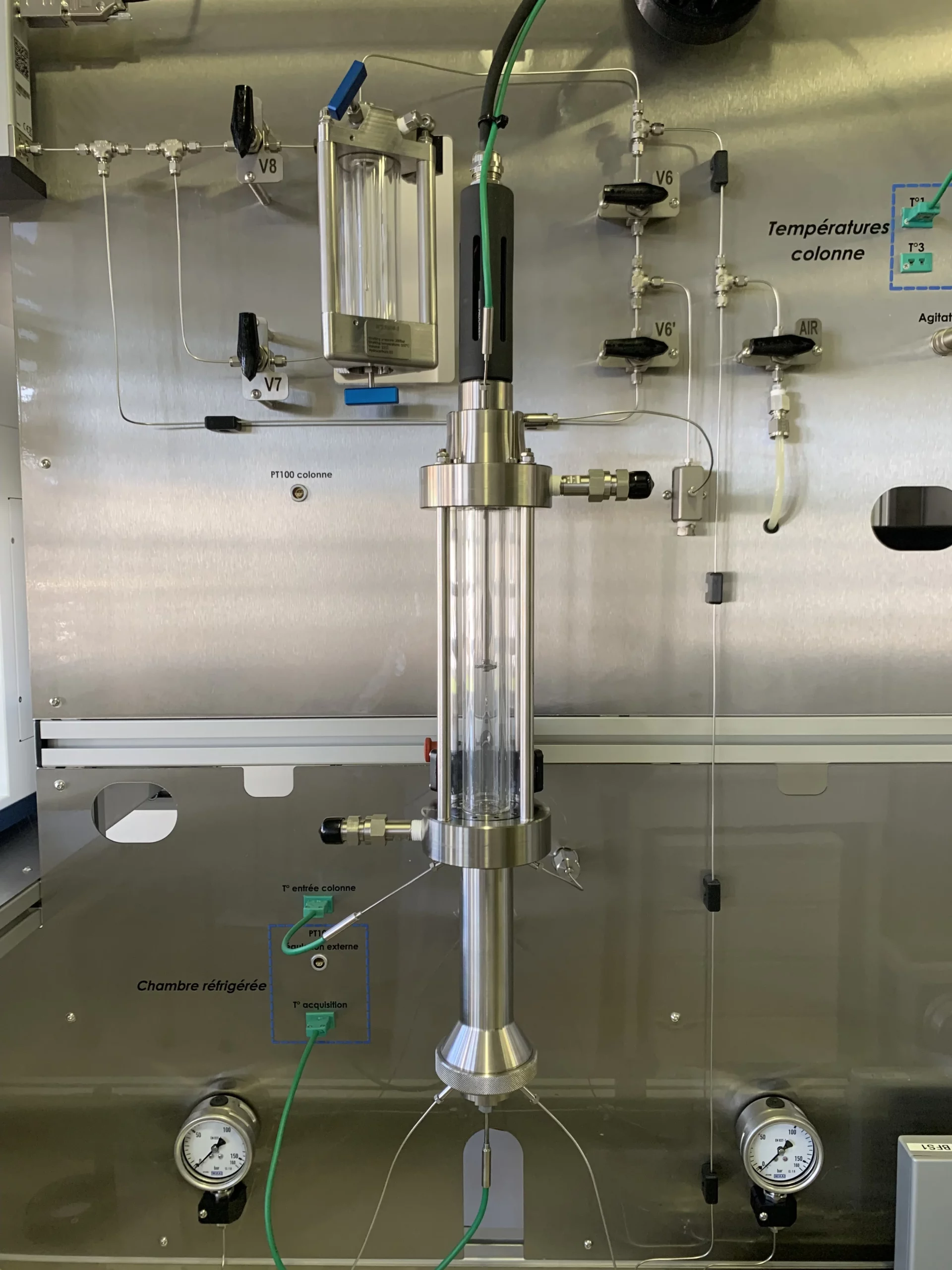

High-Pressure Visualization: The main challenge was to enable clear visual observation of hydrate formation through a sapphire tube while maintaining a service pressure of 120 bar.

Controlled Temperature: Ensure precise thermal regulation over a wide temperature range, from -10°C to +80°C.

Corrosion Resistance: Guarantee perfect compatibility with process fluids (CO2, 30 g/L salt-laden water), necessitating exceptional materials.

Experimental Versatility: The bench had to operate in two distinct and interchangeable configurations:

In a simulated porous medium (“sand pack”) with a multi-point temperature profile.

In a stirred environment with fine torque measurement to detect phase changes.

Advanced Metrology: Integrate high-precision sensors for pressure, temperature (multiple thermocouples), and stirring torque, with centralized data acquisition.

Safety and Ergonomics: Ensure complete operator safety and easy handling of the column to switch between configurations.

The Solution: A Modular Titanium Bench with Real-Time Torque Measurement

Facing this challenge, IRIAN MECATRONICS leveraged its expertise in HP/HT equipment design to deliver a fully customized solution.

Excellence in Materials: To ensure absolute corrosion resistance and analytical purity, all wetted parts (column body, heads) were machined from Titanium TA6V. The temperature probes were made of Hastelloy X, choices that highlight our mastery of materials for aggressive environments.

Innovative Modular Design: The core of our solution lies in the design of two experimental “heads,” easily interchangeable on the same sapphire column:

A “sand pack” configuration including a pre-cooling chamber for inlet fluids and an instrumented head allowing for the placement of up to 4 thermocouples at various heights within the porous medium.

A “stirring” configuration equipped with a high-speed (1500 rpm) magnetic stirrer featuring real-time torque measurement. This crucial feature allows for highly sensitive detection of hydrate formation through changes in fluid viscosity.

Visualization and Thermal Control: The transparent monocrystalline sapphire column offers a clear view of the process, allowing researchers to directly observe the nucleation and growth of hydrate crystals. It is equipped with a double jacket for the circulation of a heat-transfer fluid, ensuring uniform and precise thermal control over its entire height.

Ergonomics and Safety: To facilitate maintenance and setup changes, the column was mounted on a pivoting axis (0-180°), allowing it to be tilted safely. The bench seamlessly integrates the client’s peripheral equipment (pumps, flow meters) and secures all pressurized components behind protective plexiglass panels.

Custom Control Software: A data acquisition and control software was developed using LabVIEW, providing an intuitive interface to control stirring, display all real-time measurements (pressure, temperatures, flow rate, torque), and record test data.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.