Extreme Environment Simulation Systems / Geoscience & Subsurface Studies / Test Benches & Experimental Pilot Units

Multi-Channel HPHT Test Bench for Carbonation Studies

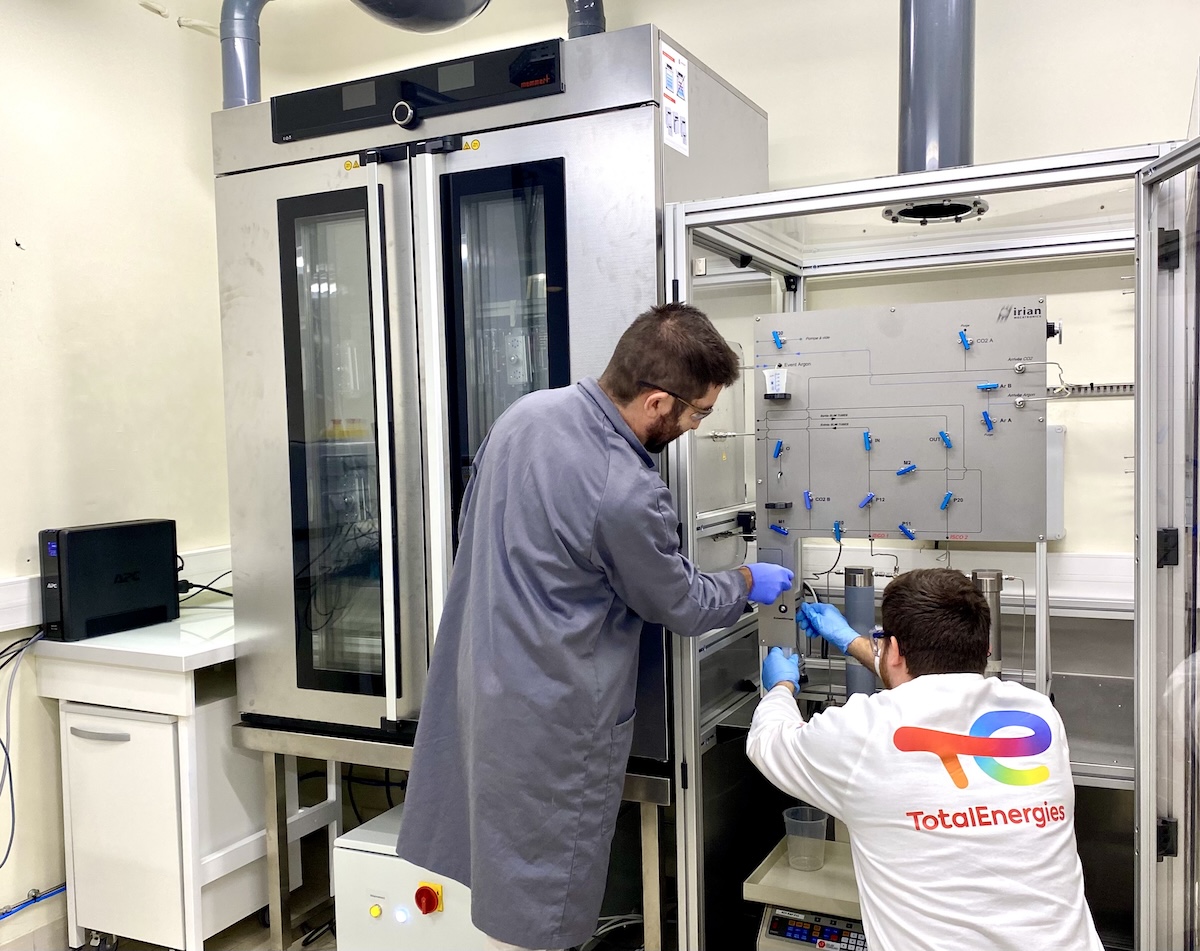

For its advanced research, a major energy group contracted IRIAN MECATRONICS to design a unique HPHT test bench. The objective was to develop a multi-channel system for carbonation studies, capable of operating up to 140 bar and 130°C. Our solution consists of a custom frame integrated into an existing oven, operating 6 parallel “slim tubes” for high-precision differential pressure measurements.

Simulating Carbonation: Specifications for a Custom HPHT Test Bench

The client needed to study the flow of CO₂-laden water through slim tubes to simulate carbonation phenomena under HPHT conditions. The primary challenge was to measure small pressure variations with very high precision in a highly corrosive environment.

- Corrosive HPHT Conditions: The system had to operate up to 140 bar and 130°C with aggressive fluids (brine, CO₂), which posed a risk of accelerated corrosion for standard steels.

- Ultra-High Measurement Precision: The process, involving very low flow rates, required pressure sensors with extreme precision and resolution (0.01 bar) to detect minute pressure drops.

- Complex Integration: The entire hydraulic circuit (6 slim tubes, valves, etc.) had to be integrated onto a custom frame inside an existing oven (Memmert UF750plus), with significant space constraints and the need for bulkhead feedthroughs.

- Automation & Control: The client wanted to control the entire process (pumps, valves, data acquisition) from a single interface, with the ability to program automated sequences.

Ensuring Precision and Durability in a Corrosive HPHT Environment

Our engineering department met the challenge by focusing on material selection, high-precision instrumentation, and seamless software integration.

- Advanced Material Selection: To counter the corrosion risk from the combination of brine, CO₂, and high temperature, we specified and implemented a solution where all wetted components (tubing, valve bodies, sensors) are made of Hastelloy C-276. This choice ensures the long-term durability of the equipment and the integrity of the measurements.

- High-Precision Instrumentation: For the critical pressure measurement, we selected Keller LEX1 sensors with Hastelloy diaphragms. These sensors provide an accuracy of 0.05% and a resolution of 0.01 bar, making it possible to quantify the slightest variations in differential pressure between the slim tubes.

- Mechanical and Software Integration: We designed a modular aluminum profile frame to support the 6 slim tubes and the valve manifold inside the oven. The entire system is controlled by a PLC and a Human-Machine Interface (HMI) developed in LabView, allowing the operator to control the pumps, automated valves, and record all data.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.