Marinized 6000m Flowmeter: Qualifying Measurement in Extreme Environments for Oceanographic Research

On behalf of a major player in oceanographic research, IRIAN MECATRONICS has studied the design of a marinized flowmeter capable of operating at depths of up to 6000 meters. The challenge was to provide an accurate flow measurement in an ultra-high-pressure environment without disturbing the scientific sample. Our engineering office developed a solution combining a non-intrusive sensor with a custom-built high-pressure containment housing.

The Challenge: Guaranteeing Scientific Measurement Accuracy at 625 bar Ambient Pressure

The scientific mission required precisely knowing the volume of water pumped by a deep-sea sampling tool. A preliminary study revealed that no standard, off-the-shelf flowmeter could meet the project’s cumulative constraints.

The specifications posed major technical challenges:

Extreme External Pressure: The equipment must withstand the ambient pressure of the seabed at 6000 meters, i.e., 625 bar.

Corrosive Environment: Total and prolonged immersion in highly corrosive seawater.

Scientific Integrity: The flowmeter must not, under any circumstances, contaminate the collected fluid.

No Flow Disturbance: The measuring instrument must not generate significant pressure losses.

Integration: The assembly had to be integrated onto a submarine vehicle, implying constraints on size and weight.

The IRIAN MECATRONICS Approach: Isolating the Sensor to Preserve the Measurement

Rather than searching for a single sensor capable of withstanding all these constraints, our design logic was to separate the functions. We selected a flow sensor for its measurement accuracy and then designed a custom environment to allow it to operate in conditions for which it was not intended.

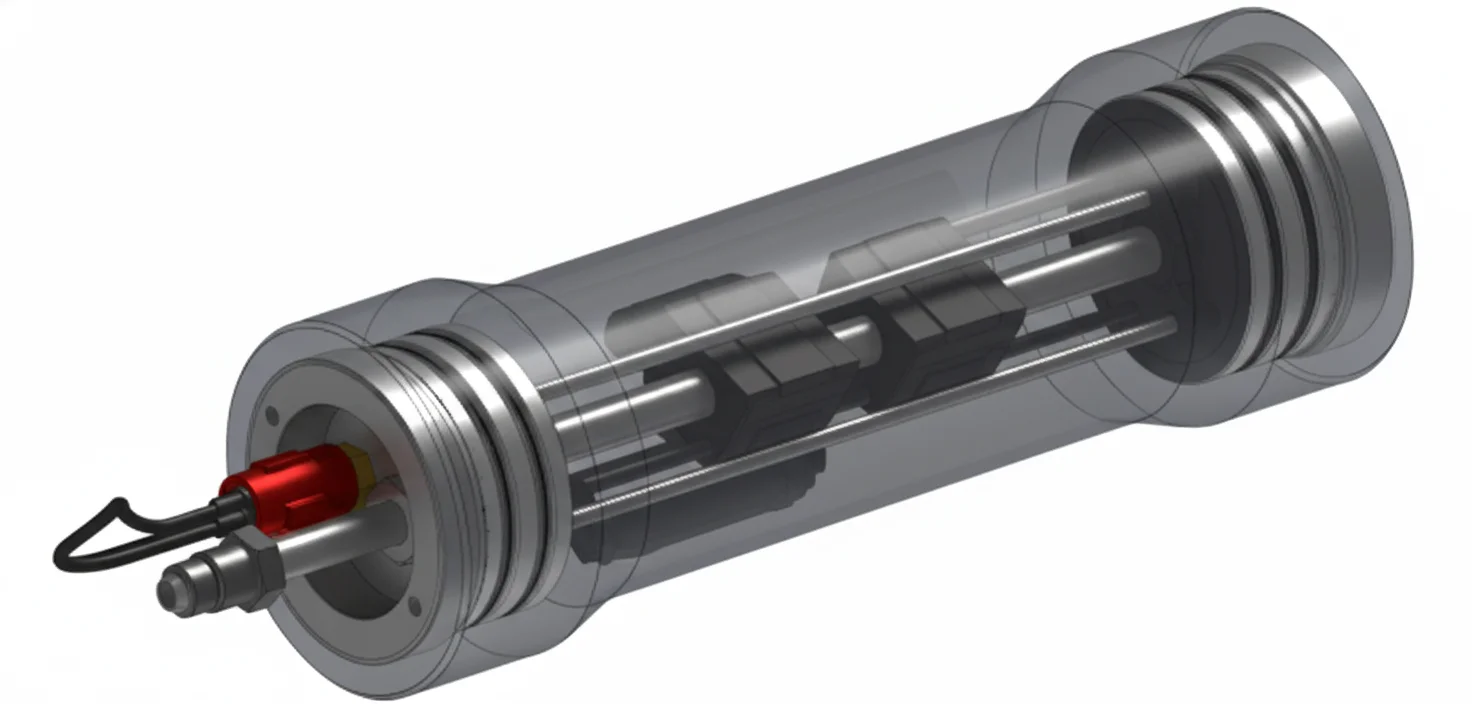

Design of an external containment housing. The heart of the solution is a cylindrical pressure cell designed to withstand an external pressure of 630 bar. This allows the flowmeter and its electronics, installed inside, to be kept at atmospheric pressure, thus completely protecting them from collapse and the marine environment. For its fabrication, we selected a stainless steel (APX4) combining high mechanical strength and excellent resistance to seawater corrosion.

Use of a non-intrusive sensor. The choice was made for an ultrasonic measurement technology. The sensor clamps around the internal tube and is therefore never in contact with the sampled seawater. This approach guarantees total scientific integrity, with no risk of fluid contamination, while also eliminating pressure loss and the risk of sensor corrosion.

Integration of high-pressure waterproof connectors. To power the sensor (24V/DC) and retrieve the measurement signal (4-20mA), a specific waterproof connector (MacArtney type) is used. This critical component ensures the absolute watertightness of the cell, guaranteeing the protection of the internal electronics and the reliability of data transmission at a depth of 6000 meters.

FAQ

Do your operating conditions require a specific design?

Complex fluids, extreme temperatures, or high pressure: our engineering team designs the vessel (Reactor or Cell) adapted to your specifications.