Wide-Range Gas Permeability Test Bench and Triaxial Cell for Geomechanics

For the School of Civil Engineering at the University of Shandong (China), which required precise rock characterization under stress, IRIAN MECATRONICS designed a custom solution. This complete system combines a wide-range gas permeability bench and a self-compensated triaxial cell, enabling accurate measurements on samples with extreme properties.

The Challenge: Characterizing Permeability Across a Wide Dynamic Range

The University of Shandong needed to measure the intrinsic gas permeability of geological samples under high confining pressure. The major difficulty lay in covering a massive permeability range without multiplying equipment, while ensuring quasi-steady flow conditions for maximum accuracy.

Specific technical constraints included:

Extreme Measurement Range: Ability to measure from $10^{-12} m^2$ to $10^{-21} m^2$, ranging from highly permeable to tight/quasi-impermeable.

High-Pressure Conditions: Application of confining pressure up to 60 MPa (600 bar) via a specific triaxial cell.

Standard Limitations: Commercial flowmeters (Bronkhorst type) are difficult to find for such a range or tedious to use as they require constant hardware changes to match the targeted permeability.

Sample Flexibility: The system had to accommodate 50mm diameter samples with variable heights from 30 to 100mm.

The IRIAN MECATRONICS Solution: Dual Measurement Circuit and Self-Compensated Cell

To meet this complex need, IRIAN MECATRONICS’ engineering department developed an architecture based on pressure variation measurement rather than standard flowmeters, ensuring greater scientific robustness.

Hybrid Architecture (Upstream/Downstream): The device is divided into two circuits. The high-pressure (upstream) circuit handles high permeabilities (10-12 to 10-16 m2), while the low-pressure (downstream) circuit measures very low permeabilities (below 10-18 m2). This design allows the detection of infinitesimal flows and breakthrough pressures that standard systems would miss, ensuring total coverage of the measurement range.

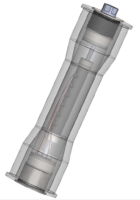

Z30C13 Steel Triaxial Cell: The provided cell is machined from Z30C13 stainless steel and features a self-compensation system. The use of this specific alloy ensures optimal mechanical and chemical resistance, while self-compensation secures sample integrity under high stress without complex operator intervention.

Darcy’s Law and Buffer Reservoirs: The method uses calibrated buffer volumes and high-precision sensors (Keller LEO-5, 0.01% accuracy). By calculating flow rate via pressure decay (Delta P / Delta t), the laboratory obtains a direct and reliable measurement based on Darcy’s law, eliminating calibration errors frequent with thermal flowmeters at very low flow rates.

Do your operating conditions require a specific design?

Complex fluids, extreme temperatures, or high pressure: our engineering team designs the vessel (Reactor or Cell) adapted to your specifications.