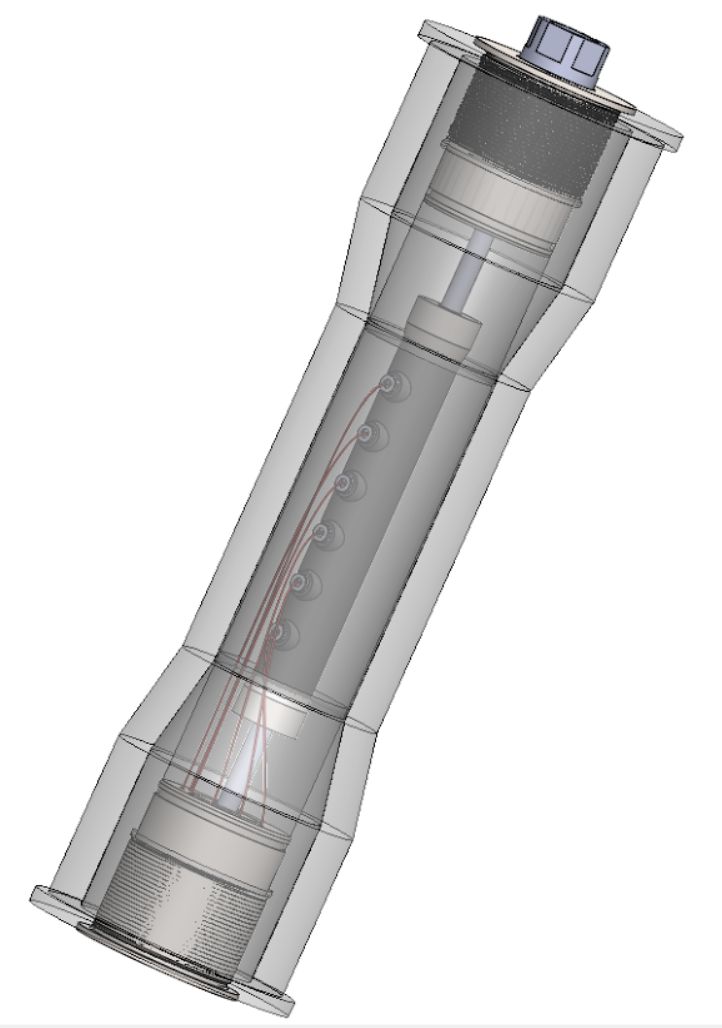

Custom X-ray Transparent Triaxial Cell for BRGM: In-Situ 3D Tomography Analysis

BRGM, the French Geological Survey, needed to visualize the internal deformation of rock samples under pressure and temperature conditions simulating deep geological environments. IRIAN MECATRONICS met this challenge by designing and manufacturing a custom, fully X-ray transparent triaxial cell for BRGM, enabling real-time 3D tomographic analysis during mechanical testing.

Technical Challenge: Simulating Extreme Geological Conditions Under X-ray Observation for BRGM

BRGM’s goal was to overcome the limitations of standard equipment, which prevents direct observation of internal micro-mechanisms (cracking, fluid flow) in a material under stress. To achieve this, their specifications included a series of complex technical constraints:

- In-situ Observation: The absolute need to visualize the rock sample’s microstructure in 3D and in real-time, without interrupting the mechanical test.

- Material Compatibility: The cell body had to be made from a material with low X-ray attenuation while withstanding high confining pressures.

- Performance and Pressure: Ability to maintain a stable hydrostatic confining pressure of up to 20 MPa (200 bar).

- Thermal Control: Requirement for precise and uniform temperature control of the sample up to 150°C.

- Advanced Instrumentation: Integration of multiple internal sensors (pore pressure, temperature) as close as possible to the sample, without creating artifacts on the X-ray image.

- Physical Integration: The cell had to fit perfectly within the confined space of an existing X-ray micro-tomography scanner, including the constraints of the rotating stage.

Custom Design: A Composite Triaxial Cell for High-Pressure 3D Imaging

To meet BRGM’s demanding specifications, the engineering team at IRIAN MECATRONICS developed a fully customized solution focused on innovative material selection and mechanical design.

Our approach centered on several key points:

- Advanced Composite Material Selection: For the cell body, we chose a high-performance carbon fiber and PEEK composite. This choice offers an optimal ratio between excellent mechanical strength to withstand high pressure and very low X-ray attenuation, ensuring high-quality tomographic images.

- Optimized Endcap Design: The top and bottom endcaps, as well as the pistons, were machined from a titanium alloy (Ti-6Al-4V). This material was selected for its high strength and low density, allowing us to design compact parts that maximize the transparent observation “window” around the sample.

- Integrated Heating and Fluid System: A cartridge heating system was integrated directly into the endcaps to ensure rapid and uniform temperature ramping. The fluid injection pathways for pore pressure management were machined inside the components to minimize the overall footprint.

- Sealed Sensor Feedthroughs: A major challenge was routing the internal sensor cables through the pressure barrier. We developed a custom, multi-channel sealed feedthrough system, ensuring reliable instrumentation with zero leakage, even at maximum pressure and temperature.

The result is a state-of-the-art piece of equipment that opens up new possibilities for geoscience research, enabling BRGM to directly correlate a material’s mechanical properties with the evolution of its 3D microstructure.

Do your operating conditions require a specific design?

Complex fluids, extreme temperatures, or high pressure: our engineering team designs the vessel (Reactor or Cell) adapted to your specifications.