12CC 600 bar Volumetric Pump for Pressure Control in Corrosive Media (Na2S) for CNRS

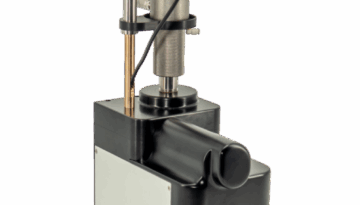

For the CNRS (Bacterial Chemistry Lab), we designed this 600 bar pump. It provides precise pressure regulation for a 500 µL observation cell.

For the CNRS (Bacterial Chemistry Lab), we designed this 600 bar pump. It provides precise pressure regulation for a 500 µL observation cell.

For an energy leader, this multi-cell bench (400 bar, 250°C) simulates formation damage from drilling fluids, including corrosive acids (HCl).

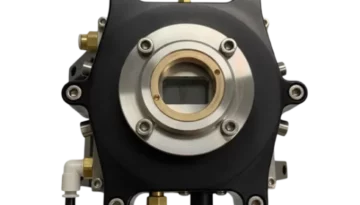

For the BRGM, we designed an X-ray transparent triaxial cell (200 bar, 150°C). Made of PEEK and titanium, it allows for in-situ 3D analysis of rocks under stress.

We carried out a complete refurbishment of two HP positive displacement pumps. The project included mechanical overhaul and modernization of the automation and user interface.

For a manufacturing leader, we designed a dual volumetric pump (200 bar) for the precision mixing of reactive fluids (polymer, abrasive suspensions).

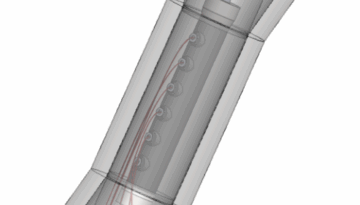

For a global energy leader, we designed this 120 bar titanium sapphire column. It allows for visualizing gas hydrate formation in corrosive environments.

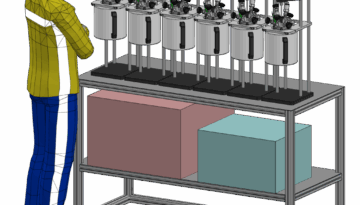

For geoscience research, we designed this bench of 6 HPHT reactors. The use of Hastelloy C276 ensures maximum resistance to corrosive fluids.

For microfluidics research, this bench injects fluids at 1000 bar into a network maintained at -70°C, offering precise control and visualization of the experiment.

This high-precision core plugging machine is designed for analysis and research. It ensures automated and reliable core sampling (up to 1000 mm long).

For ENSP (Sonatrach), we designed and delivered a turnkey PVT laboratory, including our full visualization PVT cell and custom high-pressure equipment.