Geoscience & Subsurface Studies: HPHT Laboratory Equipment

At Irian Mecatronics, we design high-performance test benchesTest Benches & Experimental Pilot Units dedicated to subsurface analysis and reservoir engineering. Our mission is to provide research laboratories with custom equipment capable of simulating deep geological conditions with extreme precision.

We specialize in High-Pressure High-Temperature (HPHT) solutions that bridge the gap between geophysics and experimental reality. Our systems are essential for characterizing rock mechanics and fluid behavior in the context of the energy transition, from geothermal energy to carbon storage.

Advanced Systems for Core Analysis & Rock Mechanics

Our expertise focuses on the physical and chemical characterization of porous media. We manufacture integrated systems that allow for the precise measurement of permeability, porosity, and mechanical strength under in-situ stress conditions.

Geomechanics & Triaxial Testing: We design stiff loading frames and triaxial cells to analyze rock deformation, acoustic emission, and failure under independent confining and pore pressures.

Core Flooding & Fluid Transport: Our core flood systems simulate the injection of complex fluids (supercritical CO₂, brine, gases) through rock samples to study reactive transport and sweep efficiency.

PVT & Fluid Properties: Custom PVT cells and analytical equipment to determine phase behavior and thermodynamic properties of reservoir fluids under dynamic conditions.

Enabling New Energy Technologies (CCUS, H2, Geothermal)

The subsurface is a critical asset for a low-carbon future. Our customized test benches allow you to de-risk projects and validate models for emerging energy sectors.

Carbon Capture & Storage (CCUS): We simulate long-term CO₂ injection to assess mineral trapping, caprock sealing integrity, and well cement durability in corrosive environments.

Deep Geothermal Energy: Our setups are engineered to test heat exchangers and material corrosion in high-temperature, high-salinity geothermal brines.

Underground Hydrogen Storage (UHS): We provide specialized setups to investigate gas diffusion, hysteresis, and microbial effects in porous reservoirs and salt caverns.

Engineering for Extreme Environments (HPHT & Corrosion)

Reliability is non-negotiable when simulating deep-earth environments. Irian Mecatronics delivers turnkey laboratory units designed to operate safely at the limits of material science.

High Pressure & Temperature: Our standard designs manage pressures up to 1000 bar (15,000 psi) and temperatures exceeding 250°C, replicating abyssal or deep-reservoir conditions.

Corrosion Resistant Materials: To handle aggressive media like H₂S or dissolved CO₂, we machine reactors and loops from noble alloys such as Titanium, Hastelloy (C-276), and Inconel.

Automated Process Control: Our benches feature smart instrumentation for the precise regulation of flow rates (low to high speed) and pressure maintenance, ensuring data quality for long-duration aging tests.

FAQ

Explore Our Custom Realizations

From initial concept to final commissioning, we support our clients in overcoming their most specific experimental challenges. The projects below illustrate our ability to design and manufacture bespoke HPHT equipment for leading energy companies and research institutes worldwide.

HPHT Test Bench for Carbonation Studies in Corrosive Media

For a major energy group, we designed an HPHT test bench (140 bar, 130°C) for carbonation studies. The Hastelloy C-276 solution resists corrosive fluids (salt water, CO2).

High-Precision Osmosis Test Bench for Argillite Studies

For the BRGM, we designed an osmosis test bench. It measures tiny liquid flows (20 µL/day) through argillite samples under 50 bar confinement.

Multi-Cell 400 bar / 250°C Test Bench for Formation Damage Analysis

For an energy leader, this multi-cell bench (400 bar, 250°C) simulates formation damage from drilling fluids, including corrosive acids (HCl).

Custom Hastelloy C276 HPHT Reactor System for Geoscience Research

For geoscience research, we designed this bench of 6 HPHT reactors. The use of Hastelloy C276 ensures maximum resistance to corrosive fluids.

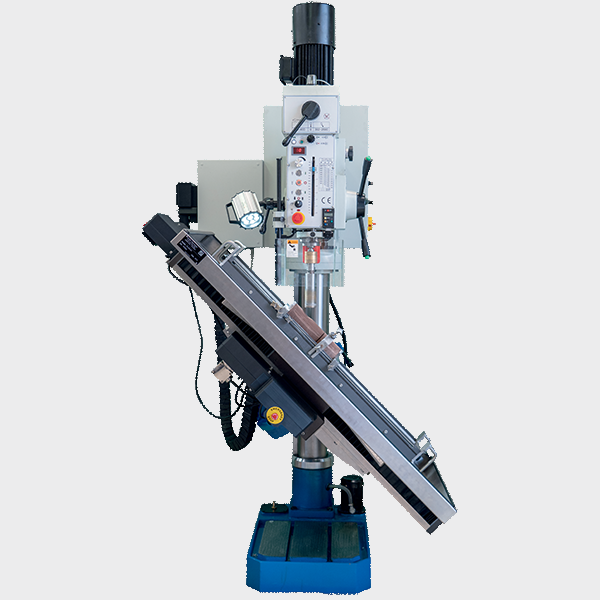

High precision core plugging machine

This high-precision core plugging machine is designed for analysis and research. It ensures automated and reliable core sampling (up to 1000 mm long).

Design and Delivery of a Turnkey PVT Laboratory with a Custom 1000 bar High-Pressure Unit

For ENSP (Sonatrach), we designed and delivered a turnkey PVT laboratory, including our full visualization PVT cell and custom high-pressure equipment.

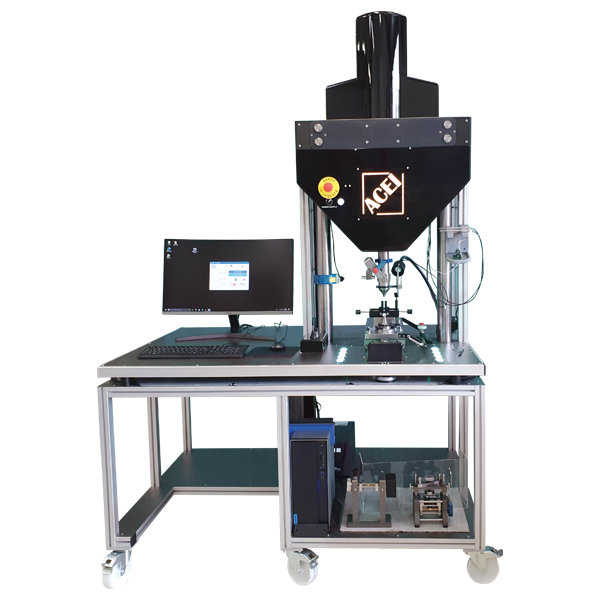

3-in-1 Uniaxial Tester (CUT) for Petroleum Rock Characterization

Design of a 3-in-1 press (20kN) for SONATRACH, combining uniaxial compression (UCS), tensile, and 3-point bending tests on one indexed mobile table.

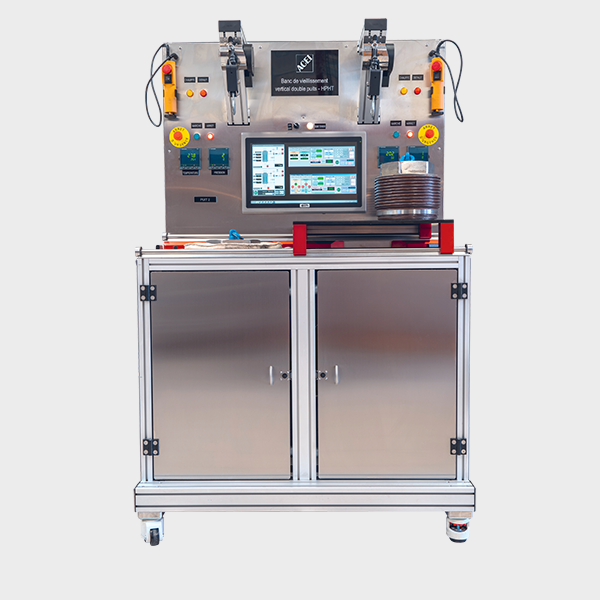

1380 bar HPHT Aging Bench: Simulating Extreme Conditions for Cement and Fluids

This accelerated aging test bench is designed to assess material durability under user-defined temperature and pressure constraints in a controlled environment.

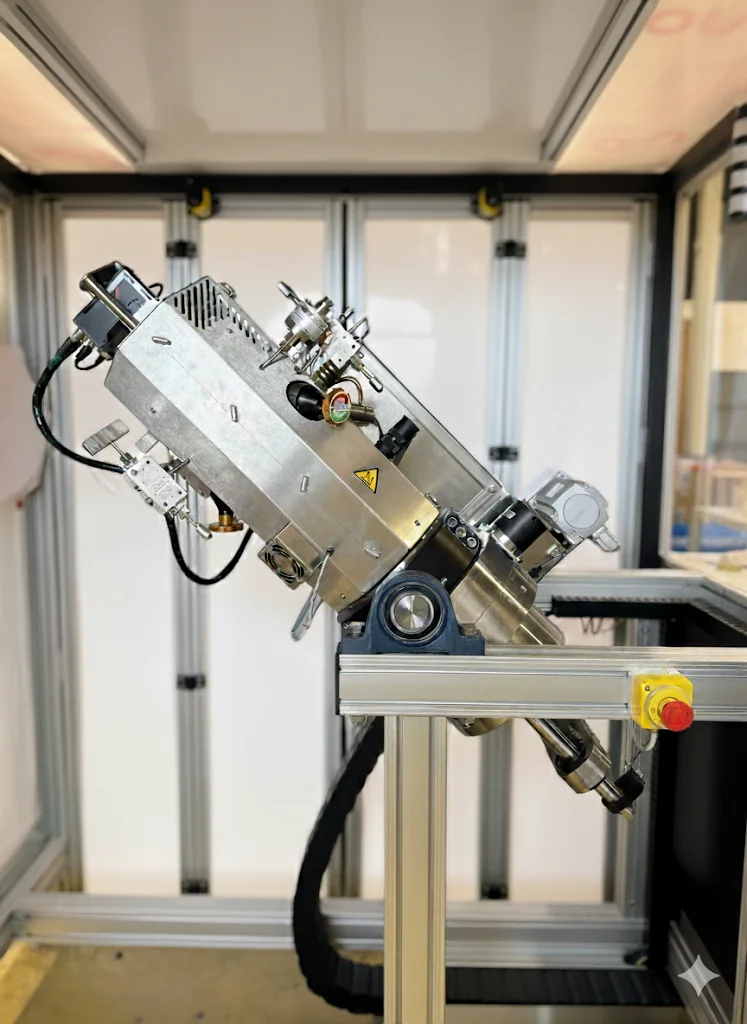

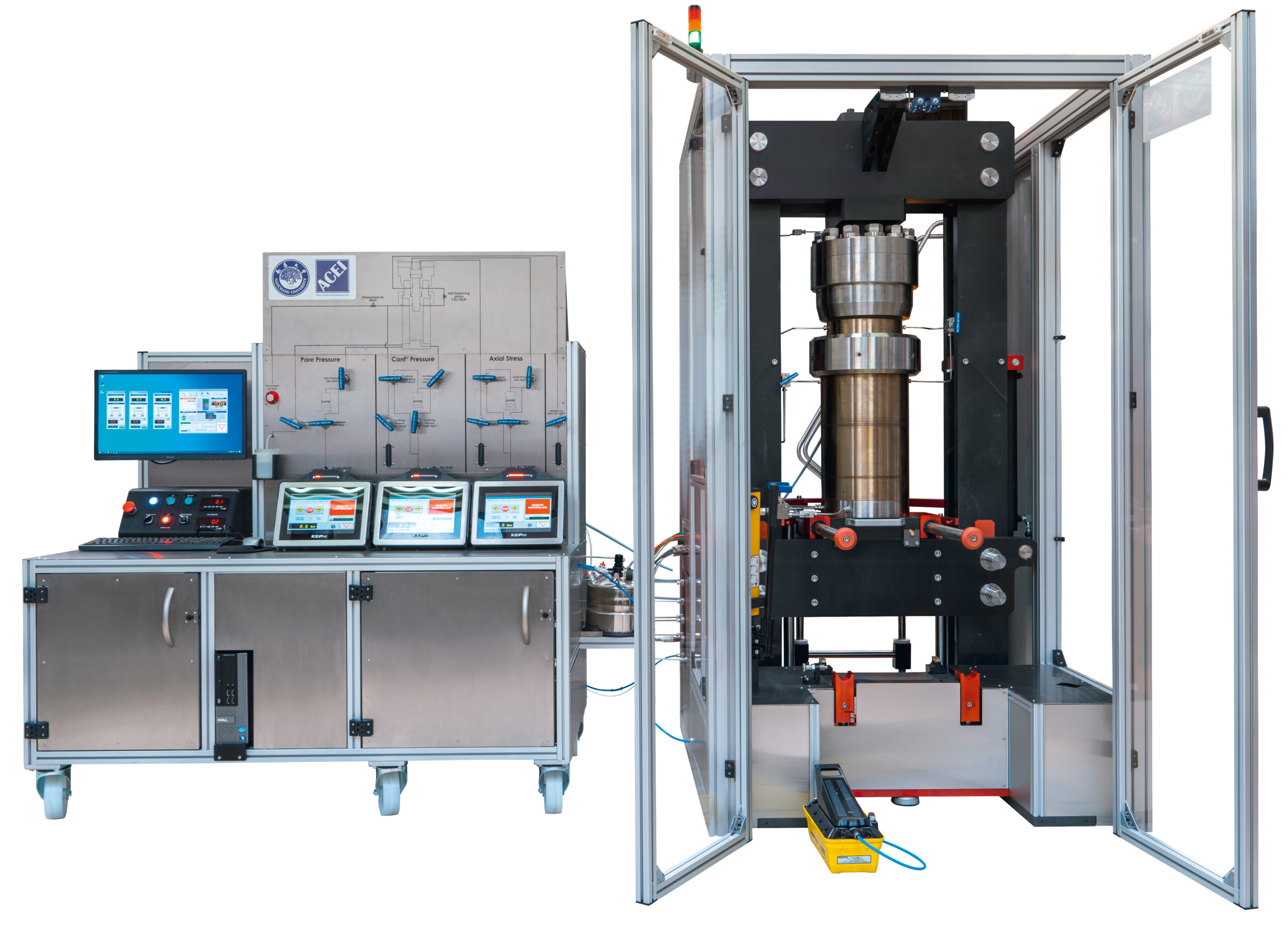

Custom HPHT Triaxial Testing Press for Geomechanics Research

This triaxial testing equipment enables in-situ analysis of rocks and cements under confining pressure, pore pressure, and axial stress, simulating geological conditions.

Does your project require specific experimental conditions?

High pressure, temperature, or critical environment: we design the custom system capable of faithfully replicating your test conditions.