High-Pressure Autoclaves for Flammable Gas (ATEX) Testing

high-pressure autoclave benches for flammable gases (H2). Features full ATEX safety integration and ergonomic handling.

Our know-how is in designing multi-physics test benches for non-standard applications, going far beyond conventional HPHT. We specialize in engineering systems that combine high pressure with other extreme physical, thermal, or chemical constraints.

This includes managing extreme thermal environments (from cryogenics to ultra-high temperatures), mastering reactive atmospheres (corrosive, explosive, flammable), or simulating non-standard physical phenomena.

Our engineering department is structured to meet novel challenges. If your specifications involve pushing the boundaries of simulation (aerospace, defense, new materials, fundamental research), we have the expertise to design the unique equipment you need.

high-pressure autoclave benches for flammable gases (H2). Features full ATEX safety integration and ergonomic handling.

For the CEREGE (CNRS) laboratory, we designed a Titanium test bench to simulate extreme deep-sea conditions (1000 bar, 2°C) for studying microorganisms.

For a major energy group, we designed an HPHT test bench (140 bar, 130°C) for carbonation studies. The Hastelloy C-276 solution resists corrosive fluids (salt water, CO2).

For an energy leader, this multi-cell bench (400 bar, 250°C) simulates formation damage from drilling fluids, including corrosive acids (HCl).

For a global energy leader, we designed this 120 bar titanium sapphire column. It allows for visualizing gas hydrate formation in corrosive environments.

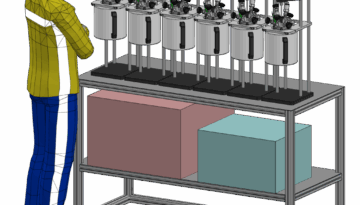

For geoscience research, we designed this bench of 6 HPHT reactors. The use of Hastelloy C276 ensures maximum resistance to corrosive fluids.

For ENSP (Sonatrach), we designed and delivered a turnkey PVT laboratory, including our full visualization PVT cell and custom high-pressure equipment.

This accelerated aging test bench is designed to assess material durability under user-defined temperature and pressure constraints in a controlled environment.

This triaxial testing equipment enables in-situ analysis of rocks and cements under confining pressure, pore pressure, and axial stress, simulating geological conditions.